Page 13 - EngineerIT January 2022

P. 13

ICT – AUGMENTED REALITY

Reduce operational injuries and fatalities

There are 2.8 million non-fatal injuries and illnesses per year

in the U.S. private industry. That represents 2.8 cases per 100

full-time workers. In 2019, the U.S. experienced the most

occupational fatalities since 2007. There was also a 3.75%

increase in injuries – 1,900 injuries per year involving days

away from work and 166 additional fatal electrical injuries.

Of all incidents, 65% occur during construction, installation,

maintenance and repair.

AR is a transformational electrical safety solution, helping to

minimize occupational injuries and fatalities:

• Provides a reduced-risk environment via augmented

animated system diagrams

• Reduces operator error with step-by-step guided

procedures

• Tailors warning and safety recommendations to local

compliance codes

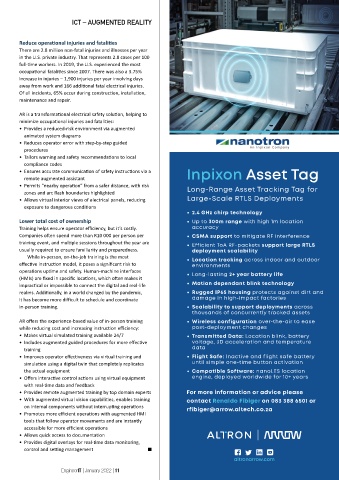

• Ensures accurate communication of safety instructions via a Inpixon Asset Tag

remote augmented assistant

• Permits “nearby operation” from a safer distance, with risk

zones and arc flash boundaries highlighted Long-Range Asset Tracking Tag for

• Allows virtual interior views of electrical panels, reducing Large-Scale RTLS Deployments

exposure to dangerous conditions

• 2.4 GHz chirp technology

Lower total cost of ownership • Up to 300m range with high 1m location

Training helps ensure operator efficiency, but it’s costly. accuracy

Companies often spend more than R10 000 per person per • CSMA support to mitigate RF interference

training event, and multiple sessions throughout the year are • Efficient ToA RF-packets support large RTLS

usually required to ensure familiarity and preparedness. deployment scalability

While in-person, on-the-job training is the most

effective instruction model, it poses a significant risk to • Location tracking across indoor and outdoor

environments

operations uptime and safety. Human-machine interfaces

(HMIs) are fixed in specific locations, which often makes it • Long-lasting 2+ year battery life

impractical or impossible to connect the digital and real-life • Motion dependant blink technology

realms. Additionally, in a world changed by the pandemic, • Rugged IP65 housing protects against dirt and

it has become more difficult to schedule and coordinate damage in high-impact factories

in-person training. • Scalability to support deployments across

thousands of concurrently tracked assets

AR offers the experience-based value of in-person training • Wireless configuration over-the-air to ease

while reducing cost and increasing instruction efficiency: post-deployment changes

• Makes virtual simulated training available 24/7 • Transmitted Data: Location blink, battery

• Includes augmented guided procedures for more effective voltage, 3D acceleration and temperature

training data

• Improves operator effectiveness via virtual training and • Flight Safe: Inactive and flight safe battery

simulation using a digital twin that completely replicates until simple one-time button activation

the actual equipment • Compatible Software: nanoLES location

• Offers interactive control actions using virtual equipment engine, deployed worldwide for 10+ years

with real-time data and feedback

• Provides remote augmented training by top domain experts For more information or advice please

• With augmented virtual vision capabilities, enables training contact Renaldo Fibiger on 083 388 6501 or

on internal components without interrupting operations rfibiger@arrow.altech.co.za

• Promotes more efficient operations with augmented HMI

tools that follow operator movements and are instantly

accessible for more efficient operations

• Allows quick access to documentation

• Provides digital overlays for real-time data monitoring,

control and setting management n

EngineerIT | January 2022 | 11