Page 50 - Energize June 2021

P. 50

TECHNICAL

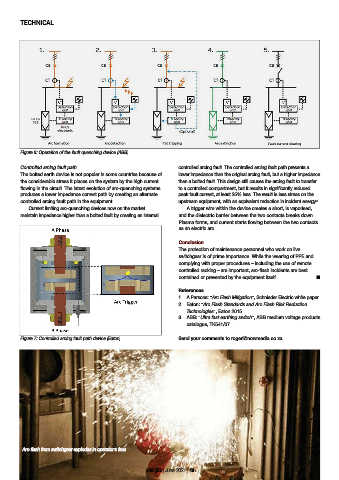

Figure 6: Operation of the fault quenching device (ABB)

Controlled arcing fault path controlled arcing fault. The controlled arcing fault path presents a

The bolted earth device is not popular in some countries because of lower impedance than the original arcing fault, but a higher impedance

the considerable stress it places on the system by the high current than a bolted fault. This design still causes the arcing fault to transfer

flowing in the circuit. The latest evolution of arc-quenching systems to a controlled compartment, but it results in significantly reduced

produces a lower impedance current path by creating an alternate peak fault current, at least 25% less. The result is less stress on the

3

controlled arcing fault path in the equipment. upstream equipment, with an equivalent reduction in incident energy.

Current limiting arc-quenching devices now on the market A trigger wire within the device creates a short, is vaporised,

maintain impedance higher than a bolted fault by creating an internal and the dielectric barrier between the two contacts breaks down.

Plasma forms, and current starts flowing between the two contacts

as an electric arc.

Conclusion

The protection of maintenance personnel who work on live

switchgear is of prime importance. While the wearing of PPE and

complying with proper procedures – including the use of remote

controlled racking – are important, arc-flash incidents are best

contained or prevented by the equipment itself. n

References

1. A Parsons: “Arc Flash Mitigation”, Schnieder Electric white paper.

2. Eaton: “Arc Flash Standards and Arc Flash Risk Reduction

Technologies”, Eaton 2015.

3. ABB: “Ultra fast earthing switch”, ABB medium voltage products

catalogue, TK541/07.

Figure 7: Controlled arcing fault path device (Eaton) Send your comments to rogerl@nowmedia.co.za

Arc-flash from switchgear explodes in operator’s face

energize | June 2021 | 48