Page 27 - Energize Issue 1 2023

P. 27

TECHNICAL

common multiblade versions have three to five blades, but

experimental versions have been created with up to 18 blades in a

ring mounting (see Figure 5a - d).

By comparing various combinations of blades, it has been

shown that a three-bladed version gives the best results, and

5

examples of these are available on the market. A commercial unit Figure 5: Multiblade SWT 4

producing 5 kW has a diameter of 1 m and a height of 1 m.

Blade shapes

Various different shaped blades have shown to improve the

efficiency of the VAWT. Examples are shown in Figure 6.

Figure 6: Different blade shapes 7

Helical blade

The diameter of the SWT is limited by the restrictions on wing tip

speed, but this limitation is overcome by making the length of the

SWT much greater than the diameter. This also favours the helical

design and allows for a gradual helix. The helical blade version

was developed in an attempt to reduce torque ripple. The blade

is of a helical form, arranged so that there is always a blade edge

facing into the wind. (Figure 7). While the helical blade always

offers a drag surface facing into the wind, there is less drag due to

the angled surface so that the surface facing into wind is always

smaller than it appears. Typically designs are two-bladed, although Figure 7: The helical SWT 2

three-bladed versions are available, and the helical version has a

high length-to-width ratio.

Darrieus model

The Darrieus model uses aerodynamics to produce lift which turns

the rotor. The basic shape is given in Figure 8 for a two-bladed

version. The most common version for urban applications is the

H-configuration, which can be either straight- or helical-bladed.

The helical DWT

The helical configuration is perhaps the most interesting, since

it allows a longer aerofoil blade to be contained within the same Figure 8: Two-bladed Darrieus wind turbine 2

rotational area as a straight-bladed turbine, thereby capturing

more of the wind and increasing efficiency. The helical version is

the most common small Darrius turbine on the market.

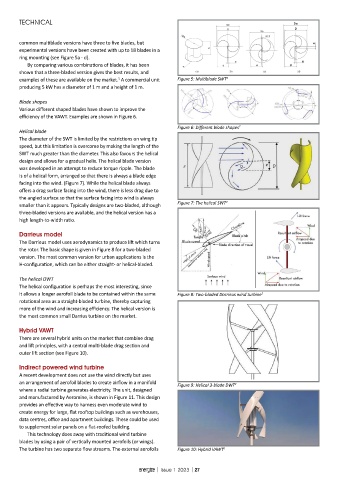

Hybrid VAWT

There are several hybrid units on the market that combine drag

and lift principles, with a central multi-blade drag section and

outer lift section (see Figure 10).

Indirect powered wind turbine

A recent development does not use the wind directly but uses

an arrangement of aerofoil blades to create airflow in a manifold Figure 9: Helical 3-blade DWT 2

where a radial turbine generates electricity. The unit, designed

and manufactured by Aeromine, is shown in Figure 11. This design

provides an effective way to harness even moderate wind to

create energy for large, flat rooftop buildings such as warehouses,

data centres, office and apartment buildings. These could be used

to supplement solar panels on a flat-roofed building.

This technology does away with traditional wind turbine

blades by using a pair of vertically mounted aerofoils (or wings).

The turbine has two separate flow streams. The external aerofoils Figure 10: Hybrid VAWT 6

energize | Issue 1 2023 | 27