Page 33 - EngineerIt May 2021

P. 33

MEASUREMENT AND INSTRUMENTATION

Why MEMS accelerometers are becoming

the designer's best choice for condition-

based monitoring applications

By Chris Murphy, Applications Engineer

Introduction to condition-based monitoring frequencies is very useful for wind turbines and other types of

The global condition-based monitoring (CbM) market has slow rotating machinery used in metal processing, pulp/paper

experienced significant growth over the past few years, and processing, and food/beverage industries where slow rotating

1

this looks set to continue. This growth coincides with the rapid speeds of assets below 60 rpm (1 Hz) are common.

advancement of MEMS accelerometers for use in vibration Figure 2 shows that when piezo-electric sensors are

sensing applications, now rivalling the once dominant piezo- exposed to large shock events they can saturate, and due

electric or PZT accelerometer. There is an increased demand for to the large RC time constant they can take a long time to

CbM on less critical assets as well as a growing adoption rate of settle back to normal. MEMS, on the other hand, matches

wireless CbM systems, and MEMS accelerometers are the key the non-contact reference sensor by settling back to normal

to this. This article will compare MEMS accelerometers to piezo- almost instantly. The implications with a piezo-electric sensor

electric accelerometers to highlight just how far MEMS sensors undergoing a severe shock mean there is a risk that valuable

have come in their short lifetime. Key design considerations information or failures in the asset/process could go undetected,

for MEMS accelerometers in CbM applications will also be while MEMS sensors will detect impact events and subsequent

discussed with a comparison of five MEMS sensors from three events reliably.

different vendors. Table 1 highlights some more advantages of MEMS

accelerometers for CbM applications. Piezo-electric

2

The current state of the art in vibration sensing — accelerometers are less suitable for wireless CbM systems

MEMS versus Piezo-electric due to a combination of size, power consumption and a

Vibration sensors have been used to detect machine health as lack of integrated features, but solutions do exist with typical

far back as the 1930s. Even now, vibration analysis is considered consumption in the range of 0.2 mA to 0.5 mA.

the most important modality for predictive maintenance (PdM). MEMS accelerometers also have a self-test feature where

Piezo-electric accelerometers have been long established as the sensor can be verified to be 100% functional. This could

the gold standard vibration sensor used on the most critical prove useful in safety critical installations where meeting system

assets to ensure they remain operational and perform efficiently. standards is made easier by the ability to verify if a deployed

Until recently, MEMS accelerometers’ limited bandwidth, noise sensor is still functional. In some applications this feature is one

performance and g-range capabilities prevented their use in CbM of the most important as it allows maintenance professionals to

of critical assets. While many high g-range accelerometers are

available (designed specifically for automotive impact detection),

they have very limited noise performance and bandwidth, making

them unsuitable for CbM. Likewise, some low noise MEMS

accelerometers (designed specifically to detect tilt) are available

but have insufficient bandwidth and g-range.

A small number of MEMS manufacturers have been striving

to overcome the noise, bandwidth, and g-range shortcomings

and have produced several medium and high performance

MEMS accelerometers with the latter being comparable to

piezo-electric accelerometers. MEMS sensors are based on

a completely different principle of operation to piezo-electric

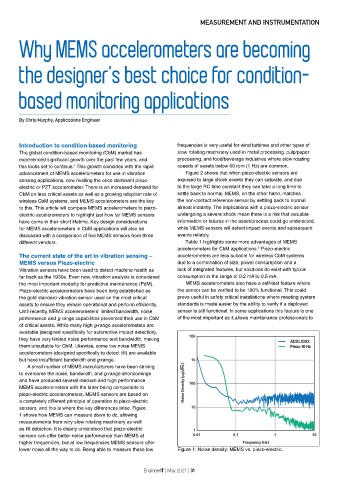

sensors, and this is where the key differences arise. Figure

1 shows how MEMS can measure down to dc, allowing

measurements from very slow rotating machinery as well

as tilt detection. It is clearly understood that piezo-electric

sensors can offer better noise performance than MEMS at

higher frequencies, but at low frequencies MEMS sensors offer

lower noise all the way to dc. Being able to measure these low Figure 1: Noise density: MEMS vs. piezo-electric.

EngineerIT | May 2021 | 31