Page 36 - EngineerIt May 2021

P. 36

MEASUREMENT AND INSTRUMENTATION

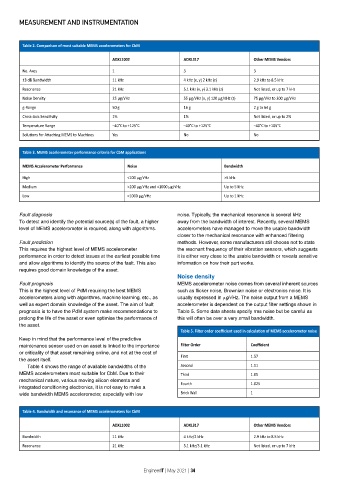

Table 2. Comparison of most suitable MEMS accelerometers for CbM

ADXL1002 ADXL317 Other MEMS Vendors

No. Axes 1 3 3

±3 dB Bandwidth 11 kHz 4 kHz (x, y) 2 kHz (z) 2.9 kHz to 8.5 kHz

Resonance 21 kHz 5.1 kHz (x, y) 3.1 kHz (z) Not listed, or up to 7 kHz

Noise Density 25 µg/√Hz 55 µg/√Hz (x, y) 120 µg/√Hz (z) 75 µg/√Hz to 300 µg/√Hz

g-Range 50 g 16 g 2 g to 64 g

Cross-Axis Sensitivity 1% 1% Not listed, or up to 2%

Temperature Range –40°C to +125°C –40°C to +125°C –40°C to +105°C

Solutions for Attaching MEMS to Machines Yes No No

Table 3. MEMS accelerometer performance criteria for CbM applications

MEMS Accelerometer Performance Noise Bandwidth

High <100 µg/√Hz >5 kHz

Medium >100 µg/√Hz and <1000 µg/√Hz Up to 5 kHz

Low >1000 µg/√Hz Up to 1 kHz

Fault diagnosis noise. Typically, the mechanical resonance is several kHz

To detect and identify the potential source(s) of the fault, a higher away from the bandwidth of interest. Recently, several MEMS

level of MEMS accelerometer is required, along with algorithms. accelerometers have managed to move the usable bandwidth

closer to the mechanical resonance with enhanced filtering

Fault prediction methods. However, some manufacturers still choose not to state

This requires the highest level of MEMS accelerometer the resonant frequency of their vibration sensors, which suggests

performance in order to detect issues at the earliest possible time it is either very close to the usable bandwidth or reveals sensitive

and allow algorithms to identify the source of the fault. This also information on how their part works.

requires good domain knowledge of the asset.

Noise density

Fault prognosis MEMS accelerometer noise comes from several inherent sources

This is the highest level of PdM requiring the best MEMS such as flicker noise, Brownian noise or electronics noise. It is

accelerometers along with algorithms, machine learning, etc., as usually expressed in µg/√Hz. The noise output from a MEMS

well as expert domain knowledge of the asset. The aim of fault accelerometer is dependent on the output filter settings shown in

prognosis is to have the PdM system make recommendations to Table 5. Some data sheets specify rms noise but be careful as

prolong the life of the asset or even optimise the performance of this will often be over a very small bandwidth.

the asset.

Table 5. Filter order coefficient used in calculation of MEMS accelerometer noise

Keep in mind that the performance level of the predictive

maintenance sensor used on an asset is linked to the importance Filter Order Coefficient

or criticality of that asset remaining online, and not at the cost of

the asset itself. First 1.57

Table 4 shows the range of available bandwidths of the Second 1.11

MEMS accelerometers most suitable for CbM. Due to their Third 1.05

mechanical nature, various moving silicon elements and Fourth 1.025

integrated conditioning electronics, it is not easy to make a

wide bandwidth MEMS accelerometer, especially with low Brick Wall 1

Table 4. Bandwidth and resonance of MEMS accelerometers for CbM

ADXL1002 ADXL317 Other MEMS Vendors

Bandwidth 11 kHz 4 kHz/2 kHz 2.9 kHz to 8.5 kHz

Resonance 21 kHz 5.1 kHz/3.1 kHz Not listed, or up to 7 kHz

EngineerIT | May 2021 | 34