Page 36 - EngineerIT April 2022

P. 36

ELECTRONICS

source. The charger will then ensure the

battery is charged to the battery’s voltage,

current and temperature specifications.

Finally, the micro-controller block

(MCU) organises the communication

between the other ICs. The MCU

communicates with the CC pin detection

IC to determine the power capability

of the power source. Then, the MCU

compares the power source’s capability

with the charger and battery’s power

needs to determine how much current

and voltage the power source should

provide. The MCU communicates the

final power settings back to the CC pin

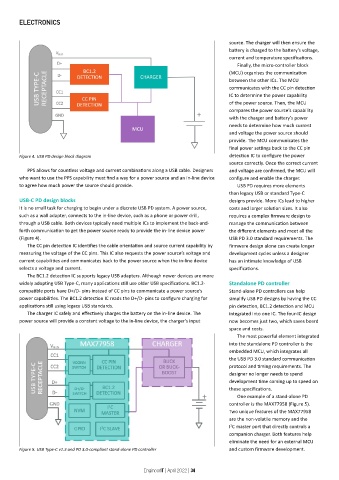

Figure 4. USB PD design block diagram detection IC to configure the power

source correctly. Once the correct current

PPS allows for countless voltage and current combinations along a USB cable. Designers and voltage are confirmed, the MCU will

who want to use the PPS capability must find a way for a power source and an in-line device configure and enable the charger.

to agree how much power the source should provide. USB PD requires more elements

than legacy USB or standard Type-C

USB-C PD design blocks designs provide. More ICs lead to higher

It is no small task for charging to begin under a discrete USB PD system. A power source, costs and larger solution sizes. It also

such as a wall adapter, connects to the in-line device, such as a phone or power drill, requires a complex firmware design to

through a USB cable. Both devices typically need multiple ICs to implement the back-and- manage the communication between

forth communication to get the power source ready to provide the in-line device power the different elements and meet all the

(Figure 4). USB PD 3.0 standard requirements. The

The CC pin detection IC identifies the cable orientation and source current capability by firmware design alone can create longer

measuring the voltage of the CC pins. This IC also requests the power source’s voltage and development cycles unless a designer

current capabilities and communicates back to the power source when the in-line device has an intimate knowledge of USB

selects a voltage and current. specifications.

The BC1.2 detection IC supports legacy USB adapters. Although newer devices are more

widely adopting USB Type-C, many applications still use older USB specifications. BC1.2- Standalone PD controller

compatible ports have D+/D- pins instead of CC pins to communicate a power source’s Stand-alone PD controllers can help

power capabilities. The BC1.2 detection IC reads the D+/D- pins to configure charging for simplify USB PD designs by having the CC

applications still using legacy USB standards. pin detection, BC1.2 detection and MCU

The charger IC safely and effectively charges the battery on the in-line device. The integrated into one IC. The four-IC design

power source will provide a constant voltage to the in-line device, the charger’s input now becomes just two, which saves board

space and costs.

The most powerful element integrated

into the standalone PD controller is the

embedded MCU, which integrates all

the USB PD 3.0 standard communication

protocol and timing requirements. The

designer no longer needs to spend

development time coming up to speed on

these specifications.

One example of a stand-alone PD

controller is the MAX77958 (Figure 5).

Two unique features of the MAX77958

are the non-volatile memory and the

I C master port that directly controls a

2

companion charger. Both features help

eliminate the need for an external MCU

Figure 5. USB Type-C v1.3 and PD 3.0-compliant stand-alone PD controller and custom firmware development.

EngineerIT | April 2022 | 34