Page 13 - EngineerIT July 2022

P. 13

ELECTRONICS

functions as the main switching circuitry automatically controls the corresponding test and measurement equipment such as the

of a buck (step-down) converter in DC supply, electronic load, and multiplexed data acquisition device (DAQ) to measure

conjunction with the LTC3861 dual, temperature, current and voltage figures directly from the demo board, and then plot

multiphase step-down voltage mode those measurements on the GUI. Important telemetry data from on-board devices are also

2

DC-to-DC controller with accurate current gathered by the software through PMBus/I C protocol. All this information is important in

sharing. comparing system efficiency and power losses.

DrMOS analysis evaluation Data and results

hardware The following test results cover the steady-state performance measurements, functional

The analysis demonstration hardware has performance waveforms, thermal measurement and output noise measurement. The

the following key features: demonstration board was tested with the following configurations:

• A PWM controller that can operate • Input voltage: 12 V

on a wide range of input and output • Output voltage: 1 V

voltages and switching frequencies. • Output load: 0 A to 60 A

In this application, the controller is • Switching frequency: 500 kHz and 1 MHz

LTC7883, a quad output polyphase

step-down DC-to-DC voltage-mode

controller, shown in Figure 2.

• Identical power stage design for both

the LTC7051 and competitor devices.

• LTpowerPlay® power system

management environment for

comprehensive telemetry of system

performance provided by the

LTC7883.

• Can withstand extended ambient

temperature in accordance with the

specified operating temperature

range of both ADI and competitor

devices.

• Board is designed for easy thermal

capture and measurement. Figure 2. Analysis demonstration board block diagram.

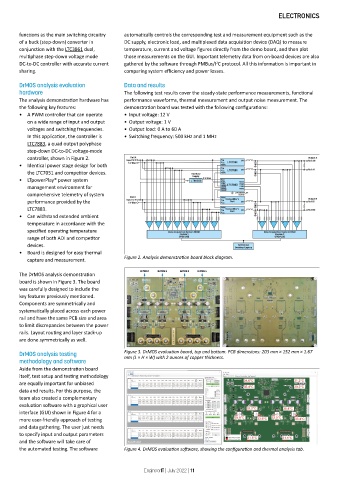

The DrMOS analysis demonstration

board is shown in Figure 3. The board

was carefully designed to include the

key features previously mentioned.

Components are symmetrically and

systematically placed across each power

rail and have the same PCB size and area

to limit discrepancies between the power

rails. Layout routing and layer stack-up

are done symmetrically as well.

DrMOS analysis testing Figure 3. DrMOS evaluation board, top and bottom. PCB dimensions: 203 mm × 152 mm × 1.67

mm (L × H × W) with 2 ounces of copper thickness.

methodology and software

Aside from the demonstration board

itself, test setup and testing methodology

are equally important for unbiased

data and results. For this purpose, the

team also created a complementary

evaluation software with a graphical user

interface (GUI) shown in Figure 4 for a

more user-friendly approach of testing

and data gathering. The user just needs

to specify input and output parameters

and the software will take care of

the automated testing. The software Figure 4. DrMOS evaluation software, showing the configuration and thermal analysis tab.

EngineerIT | July 2022 | 11