Page 13 - LandscapeSAIssue113

P. 13

FEATURE

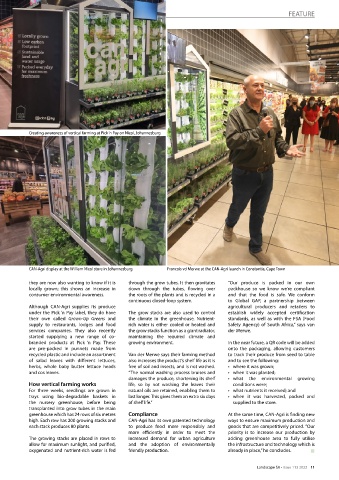

Creating awareness of vertical farming at Pick ‘n Pay on Nicol, Johannesburg

CAN-Agri display at the William Nicol store in Johannesburg Francois vd Merwe at the CAN-Agri launch in Constantia, Cape Town

they are now also wanting to know if it is through the grow tubes. It then gravitates “Our produce is packed in our own

locally grown; this shows an increase in down through the tubes, flowing over packhouse so we know we’re compliant

consumer environmental awareness. the roots of the plants and is recycled in a and that the food is safe. We conform

continuous closed-loop system. to Global GAP, a partnership between

Although CAN-Agri supplies its produce agricultural producers and retailers to

under the Pick ‘n Pay label, they do have The grow stacks are also used to control establish widely accepted certification

their own called Grown-Up Greens and the climate in the greenhouse. Nutrient- standards, as well as with the FSA (Food

supply to restaurants, lodges and food rich water is either cooled or heated and Safety Agency) of South Africa,” says van

services companies. They also recently the grow stacks function as a giant radiator, der Merwe.

started supplying a new range of co- maintaining the required climate and

branded products at Pick ‘n Pay. These growing environment. In the near future, a QR code will be added

are pre-packed in punnets made from onto the packaging, allowing customers

recycled plastic and include an assortment Van der Merwe says their farming method to track their produce from seed to table

of salad leaves with different lettuces, also increases the product’s shelf life as it is and to see the following:

herbs, whole baby butter lettuce heads free of soil and insects, and is not washed. • where it was grown;

and cos leaves. “The normal washing process bruises and • when it was planted;

damages the produce, shortening its shelf • what the environmental growing

How vertical farming works life, so by not washing the leaves their conditions were;

For three weeks, seedlings are grown in natural oils are retained, enabling them to • what nutrients it received; and

trays using bio-degradable baskets in last longer. This gives them an extra six days • when it was harvested, packed and

the nursery greenhouse, before being of shelf life.” supplied to the store.

transplanted into grow tubes in the main

greenhouse which has 24 rows of six metres Compliance At the same time, CAN-Agri is finding new

high. Each row has 200 growing stacks and CAN-Agri has its own patented technology ways to ensure maximum production and

each stack produces 80 plants. to produce food more responsibly and goods that are competitively priced. “Our

more efficiently in order to meet the priority is to increase our production by

The growing stacks are placed in rows to increased demand for urban agriculture adding greenhouse area to fully utilise

allow for maximum sunlight, and purified, and the adoption of environmentally the infrastructure and technology which is

oxygenated and nutrient-rich water is fed friendly production. already in place,” he concludes. n

Landscape SA • Issue 113 2022 11