Page 37 - Energize March 2021

P. 37

TECHNICAL

other mills included combinations of items that could be manufactured quickly in combination systems for which the design modifications

with off-the-shelf equipment, and long manufacturing lead-time items that needed to be cast. were done, or due to other plant systems

Tests on Medupi Unit 3 indicated positive results for all mill modifications, and the – of which there are many – on which no

implementation of the items with short manufacturing and procurement lead-times were modifications were done. Eskom says that

rolled out. Manufacturing of the mill items with long manufacturing lead-times were although the availability of the systems on

started immediately after the rollout decision and will be rolled out during upcoming unit which design modifications were done did

and mill outages. improve, this improvement was negated

A year after the project started, there is still a significant amount of modification work to by unforeseen once-off events in other

be done on all the remaining five units at Medupi. These include the manufacturing of long unrelated sub-systems.

lead-time items on the mills, the gas air heater operational modifications, and the boiler low Furthermore, Eskom explains that

load modifications. No work has yet commenced on the design modifications of the six units the EAF of Unit 3 was pushed down by

at Kusile. increased planned outages after the

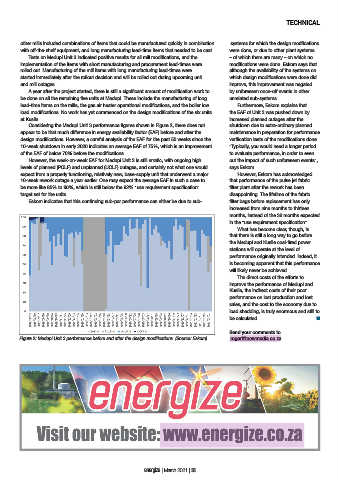

Considering the Medupi Unit 3 performance figures shown in Figure 2, there does not shutdown due to extra-ordinary planned

appear to be that much difference in energy availability factor (EAF) before and after the maintenance in preparation for performance

design modifications. However, a careful analysis of the EAF for the past 50 weeks since the verification tests of the modifications done.

10-week shutdown in early 2020 indicates an average EAF of 75%, which is an improvement “Typically, you would need a longer period

of the EAF of below 70% before the modifications. to evaluate performance, in order to even

However, the week-on-week EAF for Medupi Unit 3 is still erratic, with ongoing high out the impact of such unforeseen events”,

levels of planned (PCLF) and unplanned (UCLF) outages, and certainly not what one would says Eskom.

expect from a properly functioning, relatively new, base-supply unit that underwent a major However, Eskom has acknowledged

10-week rework outage a year earlier. One may expect the average EAF in such a case to that performance of the pulse jet fabric

be more like 85% to 90%, which is still below the 92% “use requirement specification” filter plant after the rework has been

target set for the units. disappointing. The lifetime of the fabric

Eskom indicates that this continuing sub-par performance can either be due to sub- filter bags before replacement has only

increased from nine months to thirteen

months, instead of the 36 months expected

in the “use requirement specification”.

What has become clear, though, is

that there is still a long way to go before

the Medupi and Kusile coal-fired power

stations will operate at the level of

performance originally intended. Indeed, it

is becoming apparent that this performance

will likely never be achieved.

The direct costs of the efforts to

improve the performance of Medupi and

Kusile, the indirect costs of their poor

performance on lost production and lost

sales, and the cost to the economy due to

load shedding, is truly enormous and still to

be calculated. n

Send your comments to

Figure 2: Medupi Unit 3 performance before and after the design modifications. (Source: Eskom) rogerl@nowmedia.co.za

energize | March 2021 | 35