Page 38 - Energize April 2021

P. 38

TECHNICAL

advantage during times when the turbine must operate as spinning

reserve when renewable generation is at a high level. In this scenario, the

gas turbine can be operated at very low loads and when required, is able

to deliver power very quickly because it does not need to be switched on

first. In contrast to this, single combustor gas turbines cannot be turned

down to similarly low levels and eventually would have to be turned off,

with the disadvantage of requiring longer time to get to operational state,

with penalties in engine lifetime due to start-stop cycles. 3

Ammonia as an alternative turbine fuel

Storage and transportation are essential to the successful use of

“green hydrogen”. While H 2 has the advantage of high gravimetric

a energy density, the difficulties with storage, such as large storage

volumes, the extreme low temperatures and high pressures required

for liquefaction, and limited existing infrastructure are considered

stumbling blocks in the use of H 2 as fuel for gas turbines. One solution

is to use a H 2 carrier, such as ammonia, for the transportation and

storage of the fuel, and crack it back to H 2 at the user. The properties

of ammonia make storage much easier and infrastructure to transport

ammonia already exists.

Ammonia, which is a compound consisting of H 2 and nitrogen, is a

highly efficient hydrogen carrier, and it can also be directly combusted

as fuel. Expectations are that early introduction of ammonia-based

power-generation equipment will promote ammonia’s future use as

b a carbon-free fuel. Japan for instance has produced a road map for

adoption of ammonia as a fuel. 1

Several manufacturers are developing ammonia fuelled turbines,

and the topic is being researched at several institutes. Because

ammonia has a low combustion speed, it requires a much larger

combustor. And because ammonia contains nitrogen, any system

using it as a fuel will need to tackle the “fuel NOx” generated.

Current development of 100% ammonia fuelled turbines is limited

to smaller sized turbines, although Mitsubishi Power has commenced

6

development of a 40 MW class gas turbine fuelled 100% by ammonia.

In addition, the company has developed a system which reconverts

ammonia into hydrogen and nitrogen using the exhaust heat of the gas

turbine and applies it to the hydrogen gas turbine (Figure 7).

NOx generated by the oxidation of nitrogen in the fuel by

combustion is a challenge in the direct combustion of ammonia, and

development in this area is aimed mainly at NOx reduction. 5 n

c

References

Figure 6: Sequential combustor designs (a) Ansaldo GT26, (b) Ansaldo 1. G Ceccherini, et al: “Retrofitability of DLN/DLE systems”

GT36, (c) Kawasaki 2. GE: “Can GE’s gas turbines run on hydrogen fuel?”

3. J Goldmeer: “Power to gas: hydrogen for power generation”, General

Electric Company, 2019.

4. A Ciani, et al: “Superior fuel and operational flexibility of sequential

combustion in Ansaldo Energia gas turbines”, JGPPS, October 2019.

5. ETN: “Hydrogen gas turbines: the path towards carbon zero gas turbines”,

European Turbine Network, 2020.

6. M Page-Bailey: “Mitsubishi Power developing breakthrough ammonia fired

turbine system”, Chemengonline.com, 2 March 2021.

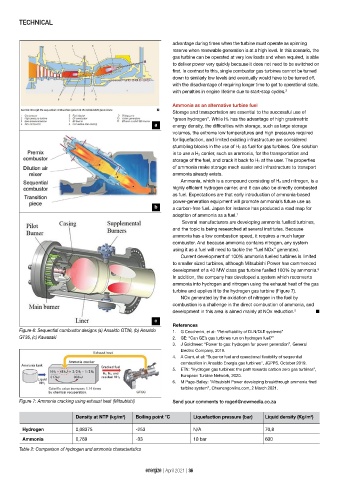

Figure 7: Ammonia cracking using exhaust heat (Mitsubishi) Send your comments to rogerl@nowmedia.co.za

3

3

Density at NTP (kg/m ) Boiling point °C Liquefaction pressure (bar) Liquid density (Kg/m )

Hydrogen 0,08375 -253 N/A 70,8

Ammonia 0,769 -33 10 bar 600

Table 2: Comparison of hydrogen and ammonia characteristics

energize | April 2021 | 36