Page 54 - Energize April 2022

P. 54

TECHNICAL

Spectrally selective coating

reduces temperature and

increases capacity of

transmission lines

BY MIKE RYCROFT, ENERGIZE

verhead conductors (OHC) are limited in their current excessive sag which could result in electrical clearance violations

carrying capacity by the maximum allowable conductor and damage to the conductor and/or line hardware.

Otemperature. OHC which operate at lower temperatures The heat generated in the conductor must be dissipated into

increase their current carrying capacity for a given cross sectional the environment to avoid overheating. The mechanisms for heat

area and reduce power losses at a specified ampacity. The transfer out of a conductor are convective cooling (wind) and

temperature of a conductor is dependant on the condition of the radiative cooling (energy radiating from the surface). The most

surface, so coatings could modify this condition to give higher common methods for establishing the relationship between

ampacity for a given conductor size. electrical current and conductor temperature are detailed in

Developments to increase the capacity of OHC by several standards such as IEEE Standard 738. At the core of these standards

percentage points could lead to a greater use of existing routes, is a heat balance equation which states that at steady state, the

and lower costs for new and reconductored routes. An area which heat coming into the conductor must equal the heat flowing

is being researched is the use of coatings to lower conductor out of the conductor. If the heat cannot diffuse fast enough the

temperatures as this promises to provide a major step forward in temperature will rise. This rise in temperature will increase the

OHC savings. amount of heat flowing out of the conductor until equilibrium is

The maximum allowable conductor temperature (MACT) is established, as given in Equation 1 (see Figure 1).

a major limiting factor on overhead transmission lines. MACT is

based on the allowable sag in the conductor and the safe operating P con + P rad = P + I R (1)

2

solar

limits of the conductor. Research into how temperatures could be

reduced for a given load, based on conductor configurations and Where: P con = convective cooling, P rad = radiative cooling,

materials, is ongoing. Benefits include lower line losses, increased P solar = solar heating, I = electrical current, R = electrical resistance

ampacity and lower reconductoring costs. (ignoring magnetic heating).

The prime focus is on the relationship between current flowing

in the cable and the temperature of the cable. This relationship On the left side of Equation 1 is heat energy flowing out of the

limits the current carrying capacity or ampacity of an overhead conductor from both convective and radiative cooling. On the

conductor. right hand side is the heat generated in the conductor by electrical

current and resistance plus the solar heat gain.

Conductor temperature is affected by several factors:

• The source of heat, including resistive heating due to current

flowing in the cable and ambient temperature, as well as direct

sunlight radiation on the cable surface

• Cooling of the cable by radiative emission and conductive cooling

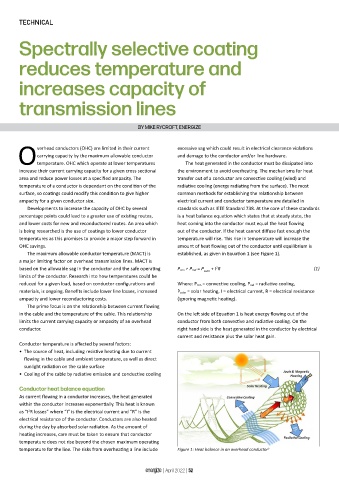

Conductor heat balance equation

As current flowing in a conductor increases, the heat generated

within the conductor increases exponentially. This heat is known

as “I R losses” where “I” is the electrical current and “R” is the

2

electrical resistance of the conductor. Conductors are also heated

during the day by absorbed solar radiation. As the amount of

heating increases, care must be taken to ensure that conductor

temperature does not rise beyond the chosen maximum operating

temperature for the line. The risks from overheating a line include Figure 1: Heat balance in an overhead conductor 5

energize | April 2022 | 52