Page 60 - Energize June 2022

P. 60

TECHNICAL

nitrogen system, a nitrogen tank or generator, or a conservator

tank equipped with a rubber diaphragm (bladder). Using inhibited

oils under these circumstances is not required, although it might

add additional protection against oil oxidation if the preservation

system were to fail. 2

Passivator content: Passivators, also known as metal deactivators,

react with reactive metal surfaces and dissolved metals such

as copper and silver and reduce their rate of reaction with

compounds in the oil. This includes oxidation reactions with

organic compounds and reactions with corrosive sulphur.

Passivators are composed of two basic types, sulphur-based a direct correlation between interfacial tension and neutralisation

and nitrogen-based. The first suggested use of passivators in number. Therefore, the interfacial tension becomes a quality

transformer oil, of which the author is aware, was in 1967 by J.J. criterion: the oil must be changed below a predefined limit.

3

Melchiore and I.W. Mills of the Sun Oil Company. As the oil ages, • If results are good, continue the regular sampling interval.

the passivator might deplete more rapidly; this depletion might • If results are fair, decrease the sampling interval.

accelerate when the oil is uninhibited. • If results are poor, check the oil for sediment and/or sludge.

• With good results, regular sample intervals can be maintained.

• With fair results, maintain regular monitoring. Corrosive sulphur: This is not a routine test. Oil is either

• When poor, it is advised to remove the oil or remove the corrosive or non-corrosive. The presence of corrosive sulphur

source of corrosivity from the oil via special oil treatment. in transformer oil and its effect on the transformer system can

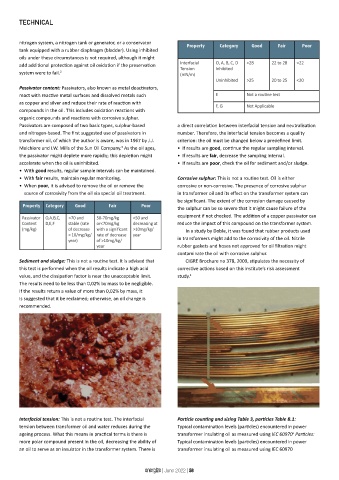

be significant. The extent of the corrosion damage caused by

the sulphur can be so severe that it might cause failure of the

equipment if not checked. The addition of a copper passivator can

reduce the impact of this compound on the transformer system.

In a study by Doble, it was found that rubber products used

in transformers might add to the corrosivity of the oil. Nitrile

rubber gaskets and hoses not approved for oil filtration might

contaminate the oil with corrosive sulphur.

Sediment and sludge: This is not a routine test. It is advised that CIGRE Brochure no 378, 2009, stipulates the necessity of

this test is performed when the oil results indicate a high acid corrective actions based on this institute’s risk assessment

value, and the dissipation factor is near the unacceptable limit. study. 4

The results need to be less than 0,02% by mass to be negligible.

If the results return a value of more than 0,02% by mass, it

is suggested that it be reclaimed; otherwise, an oil change is

recommended.

Interfacial tension: This is not a routine test. The interfacial Particle counting and sizing Table 3, particles Table B.1:

tension between transformer oil and water reduces during the Typical contamination levels (particles) encountered in power

ageing process. What this means in practical terms is there is transformer insulating oil as measured using IEC 60970 Particles:

5

more polar compound present in the oil, decreasing the ability of Typical contamination levels (particles) encountered in power

an oil to serve as an insulator in the transformer system. There is transformer insulating oil as measured using IEC 60970

energize | June 2022 | 58