Page 77 - Energize July 2022

P. 77

TECHNICAL

produced from fossil fuels such as methane and the ready Natural gas (methane) fuel cell

availability of “green hydrogen”, produced by electrolysis of water Natural gas is the most readily available fuel for fuel cells and a

using “surplus” renewable energy, is somewhere in the future. number of commercial systems are available. Numerous fuel cells of

To tackle the difficulties related to hydrogen, hydrogen carriers this type are in use worldwide ranging from single systems rated at

have been suggested. Such fuels include methanol, ethanol, 10 kW to those greater than 1 MW. There are also very large multi-

methane and ammonia. Organic-based fuels, such as methanol, unit systems which produce between 10 and 60 MW (see Figure 10).

ethanol and methane, contain carbon and so will release CO 2 upon

utilisation. This has driven development towards nitrogen-based

carriers such as ammonia and hydrazine. Ammonia contains 17,6

wt% hydrogen and, unlike ethanol and methanol, contains no

carbon and therefore will not release CO 2 on decomposition.

Liquid fuel types are not as efficient as pure hydrogen, as the

hydrogen needs to be “stripped” off the fuel molecule and then

used in the fuel cell. Two methods are in use:

• Pre-reforming: The liquid or gaseous fuel is processed to release

the hydrogen in a pre-treatment section, and the resulting Figure 10: World’s largest fuel cell plant (78 MW) at Incheon, S Korea

hydrogen fed to the fuel cell. (Hydrogen central)

• Direct use: Hydrogen is extracted from the fuel inside the FC.

Low-temperature fuel cells (AFC, PEM, PAFC) require a reformer

external to the fuel cell stack. Developers of stationary PEM fuel

cell power plants have produced integrated packages which

combine fuel processing, power production stacks and inverter

sections into compact products.

SOFC and MCFC systems operate at sufficiently high

temperatures to reform natural gas and other carriers internal

to the fuel cell stack. This eliminates the need for an external

reformer, resulting in a potentially simpler and lower-cost fuel cell

system. Figure 11: Commercial methane powered 400 kW fuel cell system (UTC)

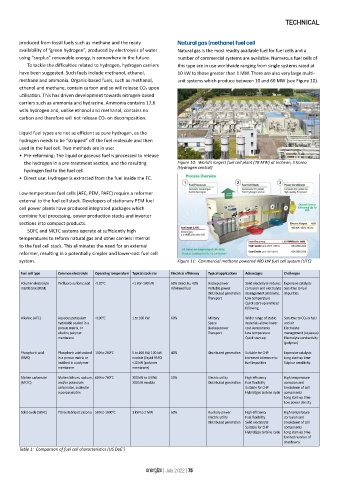

Fuel cell type Common electrolyte Operating temperature Typical stack size Electrical efficiency Typical applications Advantages Challenges

Polymer electrolyte Perfluoro-sulfonic acid <120°C <1 kW–100 kW 60% direct H2; 40% Backup power Solid electrolyte reduces Expensive catalysts

membrane (PEM) reformed fuel Portable power corrosion and electrolyte Sensitive to fuel

Distributed generation management problems. impurities

Transport Low temperature

Quick start-up and load

following

Alkaline (AFC) Aqueous potassium <100°C 1 to 100 kW 60% Military Wider range of stable Sensitive to CO2 in fuel

hydroxide soaked in a Space materials allows lower and air

porous matrix, or Backup power cost components Electrolyte

alkaline polymer Transport Low temperature management (aqueous)

membrane Quick start-up Electrolyte conductivity

(polymer)

Phosphoric acid Phosphoric acid soaked 150 to 200°C 5 to 400 kW, 100 kW 40% Distributed generation Suitable for CHP Expensive catalysts

(PAFC) in a porous matrix or module (liquid PAFC) Increased tolerance to Long start-up time

imbibed in a polymer <10 kW (polymer fuel impurities Sulphur sensitivity

membrane membrane)

Molten carbonate Molten lithium, sodium, 600 to 700°C 300 kW to 3 MW, 50% Electric utility High efficiency High temperature

(MCFC) and/or potassium 300 kW module Distributed generation Fuel flexibility corrosion and

carbonates, soaked in Suitable for CHP breakdown of cell

a porous matrix Hybrid/gas turbine cycle components

Long start-up time

Low power density

Solid oxide (SOFC) Yttria stabilized zirconia 500 to 1000°C 1 kW to 2 MW 60% Auxiliary power High efficiency High temperature

Electric utility Fuel flexibility corrosion and

Distributed generation Solid electrolyte breakdown of cell

Suitable for CHP components

Hybrid/gas turbine cycle Long start-up time

Limited number of

shutdowns

Table 1: Comparison of fuel cell characteristics (US DoE )

1

energize | July 2022 | 75