Page 5 - Energize Issue 1 2023

P. 5

COVER STORY

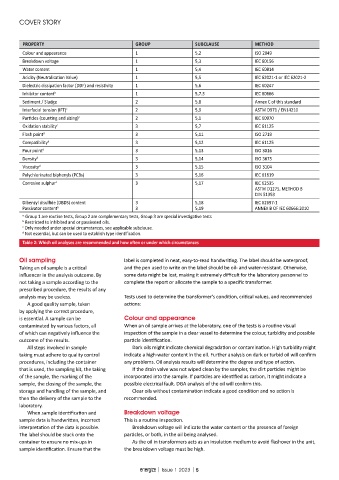

PROPERTY GROUP SUBCLAUSE METHOD

Colour and appearance 1 5,2 ISO 2049

Breakdown voltage 1 5,3 IEC 60156

Water content 1 5,4 IEC 60814

Acidity (Neutralisation Value) 1 5,5 IEC 62021-1 or IEC 62021-2

Dielectric dissipation factor (DDF) and resistivity 1 5,6 IEC 60247

Inhibitor content b 1 5,7.3 IEC 60666

Sediment / Sludge 2 5,8 Annex C of this standard

Interfacial tension (IFT) c 2 5,9 ASTM D971 / EN14210

Particles (counting and sizing) c 2 5,1 IEC 60970

Oxidation stability c 3 5,7 IEC 61125

Flash point d 3 5,11 ISO 2719

Compatibility d 3 5,12 IEC 61125

Pour point d 3 5,13 ISO 3016

Density d 3 5,14 ISO 3675

Viscosity d 3 5,15 ISO 3104

Polychlorinated biphenyls (PCBs) 3 5,16 IEC 61619

Corrosive sulphur c 3 5,17 IEC 62535

ASTM D1275, METHOD B

DIN 51353

Dibenzyl disulfide (DBDS) content 3 5,18 IEC 62697-1

Passivator content b 3 5,19 ANNEX B OF IEC 60666:2010

a Group 1 are routine tests, Group 2 are complementary tests, Group 3 are special investigative tests

b Restricted to inhibited and or passivated oils.

c Only needed under special circumstances, see applicable subclause.

d Not essential, but can be used to establish type identification.

Table 2: Which oil analyses are recommended and how often or under which circumstances

Oil sampling label is completed in neat, easy-to-read handwriting. The label should be waterproof,

Taking an oil sample is a critical and the pen used to write on the label should be oil- and water-resistant. Otherwise,

influencer in the analysis outcome. By some data might be lost, making it extremely difficult for the laboratory personnel to

not taking a sample according to the complete the report or allocate the sample to a specific transformer.

prescribed procedure, the results of any

analysis may be useless. Tests used to determine the transformer’s condition, critical values, and recommended

A good quality sample, taken actions:

by applying the correct procedure,

is essential. A sample can be Colour and appearance

contaminated by various factors, all When an oil sample arrives at the laboratory, one of the tests is a routine visual

of which can negatively influence the inspection of the sample in a clear vessel to determine the colour, turbidity and possible

outcome of the results. particle identification.

All steps involved in sample Dark oils might indicate chemical degradation or contamination. High turbidity might

taking must adhere to quality control indicate a high-water content in the oil. Further analysis on dark or turbid oil will confirm

procedures, including the container any problems. Oil analysis results will determine the degree and type of action.

that is used, the sampling kit, the taking If the drain valve was not wiped clean by the sampler, the dirt particles might be

of the sample, the marking of the incorporated into the sample. If particles are identified as carbon, it might indicate a

sample, the closing of the sample, the possible electrical fault. DGA analysis of the oil will confirm this.

storage and handling of the sample, and Clear oils without contamination indicate a good condition and no action is

then the delivery of the sample to the recommended.

laboratory.

When sample identification and Breakdown voltage

sample data is handwritten, incorrect This is a routine inspection.

interpretation of the data is possible. Breakdown voltage will indicate the water content or the presence of foreign

The label should be stuck onto the particles, or both, in the oil being analysed.

container to ensure no mix-ups in As the oil in transformers acts as an insulation medium to avoid flashover in the unit,

sample identification. Ensure that the the breakdown voltage must be high.

energize | Issue 1 2023 | 5