Page 32 - Energize April 2021

P. 32

TECHNICAL

Managing transmission voltages

in power systems

by Ricardo Carvalho Campos, André Lanza de Oliveira e Silva, Marcelo Ricardo de Moraes, Jari Kotiniitty and Tommi Keikko, GE Grid Solutions

During normal conditions, the operating voltages of transmission and distribution systems must be

maintained within very tight limits, typically, from 0,95 to 1,05 p.u. of the rated value. At low system

loading, operating voltages increase due to the capacitive nature of the grid. Shunt reactors are then

used to absorb this excess reactive power generated by the grid’s capacitances and thereby regulate the

operating voltages of transmission and distribution systems.

his document presents useful information on the Design of dry type air core shunt reactors

application and specification of shunt reactors Typically, dry type air core reactors for shunt application are

Tfor transmission and distribution power systems, designed using fiberglass encapsulated construction. The winding

describing how voltage control is achieved. It also provides consists of numerous insulated aluminium conductors, which are

a brief explanation of the design aspects and benefits of mechanically immobilised and encapsulated in epoxy impregnated

using dry type air core shunt reactors, including switching, fiberglass filaments, forming cylinders (or layers).

protection, and grounding. Depending on the reactor’s ratings, one or more cylinders

are connected in parallel between the aluminium spiders. The

Benefits of air core dry type shunt reactors individual cylinders are separated by vertically oriented fiberglass

Dry type air core shunt reactors are a very cost-effective spacers, forming cooling ducts for heat dissipation by means of

solution for reactive power compensation of transmission and air flow from the bottom to the top of winding. This construction

distribution systems. Their feasibility depends primarily on allows the use of compact coils even for high inductance, reducing

the combination of required voltage and power. Nowadays, installation footprint.

they can be installed in system voltages up to 500kV, being Medium voltage shunt reactors are typically designed with

connected directly to substation busbars, transmission line a single coil per phase. For high voltage applications, the shunt

endings or tertiary windings of large power transformers. reactors can be split into two or more coils in series per phase, in

order to meet insulation requirements (dielectric creepage length).

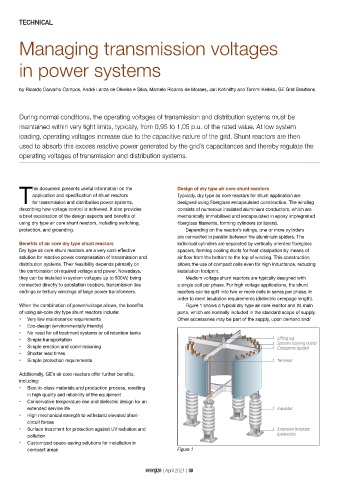

When the combination of power/voltage allows, the benefits Figure 1 shows a typical dry type air core reactor and its main

of using air-core dry type shunt reactors include: parts, which are normally included in the standard scope of supply.

• Very low maintenance requirements Other accessories may be part of the supply, upon demand and/

• Eco-design (environmentally friendly)

• No need for oil treatment systems or oil retention tanks

• Simple transportation

• Simple erection and commissioning

• Shorter lead times

• Simple protection requirements

Additionally, GE’s air core reactors offer further benefits,

including:

• Best-in-class materials and production process, resulting

in high quality and reliability of the equipment

• Conservative temperature rise and dielectric design for an

extended service life

• High mechanical strength to withstand elevated short-

circuit forces

• Surface treatment for protection against UV radiation and

pollution

• Customized space-saving solutions for installation in

compact areas Figure 1

energize | April 2021 | 30