Page 40 - Energize August 2021

P. 40

TECHNICAL

density B S of 1,63T, which is small compared to silicon steel

(2,0 to 2,1 T). As a result, the cross-sectional area of an AM

core is about 1,3 times as large as that of SST with same power

capacity. This makes windings longer, with an increase in load

loss. However, the average load factor of many distribution

transformers is 30% to 50%, so the reduction of iron loss

outweighs an increase in copper loss. The additional copper

losses could result in the AMDT efficiency being equal to or

lower than CRGO efficiency at high loads (Figure 7). Table 3

provides figures for a typical manufacturer.

The other significant difference between amorphous core

Figure 5: Laminated AM cores 4

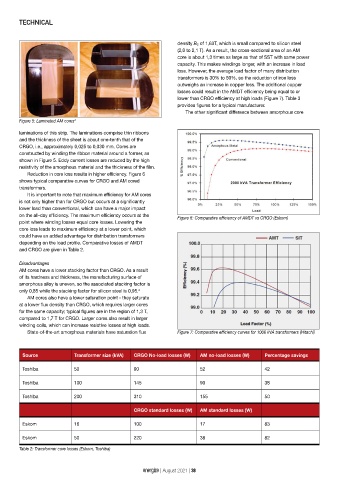

laminations of this strip. The laminations comprise thin ribbons

and the thickness of the sheet is about one-tenth that of the

CRGO, i.e., approximately 0,025 to 0,030 mm. Cores are

constructed by winding the ribbon material around a former, as

shown in Figure 5. Eddy current losses are reduced by the high

resistivity of the amorphous material and the thickness of the film.

Reduction in core loss results in higher efficiency. Figure 6

shows typical comparative curves for CRGO and AM cored

transformers.

It is important to note that maximum efficiency for AM cores

is not only higher than for CRGO but occurs at a significantly

lower load than conventional, which can have a major impact

on the all-day efficiency. The maximum efficiency occurs at the

Figure 6: Comparative efficiency of AMDT vs CRGO (Eskom)

point where winding losses equal core losses. Lowering the

core loss leads to maximum efficiency at a lower point, which

could have an added advantage for distribution transformers

depending on the load profile. Comparative losses of AMDT

and CRGO are given in Table 2.

Disadvantages

AM cores have a lower stacking factor than CRGO. As a result

of its hardness and thickness, the manufacturing surface of

amorphous alloy is uneven, so the associated stacking factor is

only 0,85 while the stacking factor for silicon steel is 0,95. 3

AM cores also have a lower saturation point - they saturate

at a lower flux density than CRGO, which requires larger cores

for the same capacity; typical figures are in the region of 1,3 T,

compared to 1,7 T for CRGO. Larger cores also result in larger

winding coils, which can increase resistive losses at high loads.

State-of-the-art amorphous materials have saturation flux Figure 7: Comparative efficiency curves for 1000 kVA transformers (Hitachi)

Source Transformer size (kVA) CRGO No-load losses (W) AM no-load losses (W) Percentage savings

Toshiba 50 90 52 42

Toshiba 100 145 90 38

Toshiba 200 310 155 50

CRGO standard losses (W) AM standard losses (W)

Eskom 16 100 17 83

Eskom 50 220 38 82

Table 2: Transformer core losses (Eskom, Toshiba)

energize | August 2021 | 38