Page 58 - Energize August 2021

P. 58

TECHNICAL

Extreme overloads can result in

catastrophic transformer failure. The

temperature of the top oil should

never exceed 100°C for power

transformers with 55°C insulation or

110°C for those with 65°C insulation.

The consequence of exceeding these

limits could be oil overflow, excessive

pressure, or tank rupture.

If winding hot spot temperatures

exceed 140°C when moisture is

present, free bubbles may form and

result in internal faults. Due to these

considerations, the peak short duration

loading of power transformers less than

100 MVA should never exceed 200% of

the nameplate rating.

The resulting fault current passes

Figure 1: Distribution transformer at substation

through the transformer and shakes

the windings with a mechanical force

proportional to the square of the fault

current magnitude. If thermal aging

has caused the insulation to become

sufficiently brittle, a crack will form and an

internal transformer fault will result.

Low impedance transformers

tend to fail more often than high

impedance transformers since they will

experience more severe fault currents.

Autotransformers generally have very low

impedances and tend to fail more often

than multiple-winding transformers.

Extensive research has been done

in the area of transformer condition

assessment. The goal is to determine

the health of the transformer and

identify incipient problems before they

lead to catastrophic failure. Simple

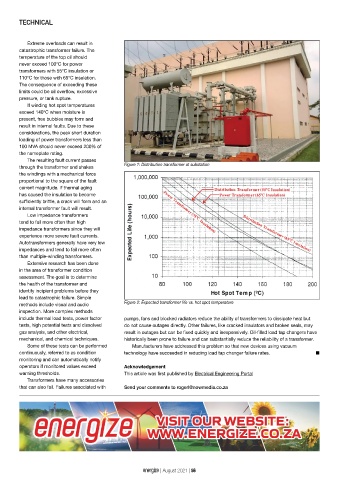

Figure 2: Expected transformer life vs. hot spot temperature

methods include visual and audio

inspection. More complex methods

include thermal load tests, power factor pumps, fans and blocked radiators reduce the ability of transformers to dissipate heat but

tests, high potential tests and dissolved do not cause outages directly. Other failures, like cracked insulators and broken seals, may

gas analysis, and other electrical, result in outages but can be fixed quickly and inexpensively. Oil-filled load tap changers have

mechanical, and chemical techniques. historically been prone to failure and can substantially reduce the reliability of a transformer.

Some of these tests can be performed Manufacturers have addressed this problem so that new devices using vacuum

continuously, referred to as condition technology have succeeded in reducing load tap changer failure rates. n

monitoring and can automatically notify

operators if monitored values exceed Acknowledgement

warning thresholds. This article was first published by Electrical Engineering Portal

Transformers have many accessories

that can also fail. Failures associated with Send your comments to rogerl@nowmedia.co.za

energize | August 2021 | 56