Page 57 - Energize August 2021

P. 57

TECHNICAL

Common failure modes of

distribution electrical equipment

by Edvard Csanyi, EEP

ach piece of electrical equipment

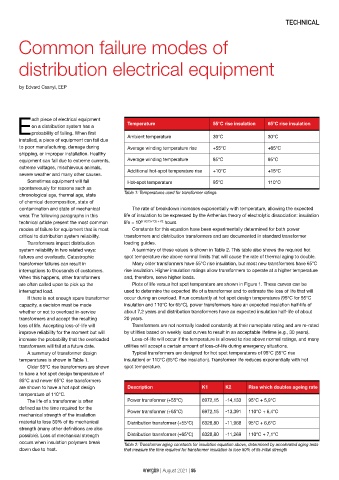

Temperature 55°C rise insulation 65°C rise insulation

on a distribution system has a

Eprobability of failing. When first

Ambient temperature 30°C 30°C

installed, a piece of equipment can fail due n

to poor manufacturing, damage during Average winding temperature rise +55°C +65°C

shipping, or improper installation. Healthy

equipment can fail due to extreme currents, Average winding temperature 85°C 95°C

extreme voltages, mischievous animals,

Additional hot-spot temperature rise +10°C +15°C

severe weather and many other causes.

Sometimes equipment will fail Hot-spot temperature 95°C 110°C

spontaneously for reasons such as

Table 1: Temperatures used for transformer ratings

chronological age, thermal age, state

of chemical decomposition, state of

contamination and state of mechanical The rate of breakdown increases exponentially with temperature, allowing the expected

wear. The following paragraphs in this life of insulation to be expressed by the Arrhenius theory of electrolytic dissociation: insulation

technical article present the most common life = 10 (K1/(273+°C)) + K2 hours

modes of failure for equipment that is most Constants for this equation have been experimentally determined for both power

critical to distribution system reliability. transformers and distribution transformers and are documented in standard transformer

Transformers impact distribution loading guides.

system reliability in two related ways: A summary of these values is shown in Table 2. This table also shows the required hot

failures and overloads. Catastrophic spot temperature rise above normal limits that will cause the rate of thermal aging to double.

transformer failures can result in Many older transformers have 55°C rise insulation, but most new transformers have 65°C

interruptions to thousands of customers. rise insulation. Higher insulation ratings allow transformers to operate at a higher temperature

When this happens, other transformers and, therefore, serve higher loads.

are often called upon to pick up the Plots of life versus hot spot temperature are shown in Figure 1. These curves can be

interrupted load. used to determine the expected life of a transformer and to estimate the loss of life that will

If there is not enough spare transformer occur during an overload. If run constantly at hot spot design temperatures (95°C for 55°C

capacity, a decision must be made insulation and 110°C for 65°C), power transformers have an expected insulation half-life of

whether or not to overload in-service about 7,2 years and distribution transformers have an expected insulation half-life of about

transformers and accept the resulting 20 years.

loss of life. Accepting loss-of-life will Transformers are not normally loaded constantly at their nameplate rating and are re-rated

improve reliability for the moment but will by utilities based on weekly load curves to result in an acceptable lifetime (e.g., 30 years).

increase the probability that the overloaded Loss-of-life will occur if the temperature is allowed to rise above normal ratings, and many

transformers will fail at a future date. utilities will accept a certain amount of loss-of-life during emergency situations.

A summary of transformer design Typical transformers are designed for hot spot temperatures of 95°C (55°C rise

temperatures is shown in Table 1. insulation) or 110°C (65°C rise insulation). Transformer life reduces exponentially with hot

Older 55°C rise transformers are shown spot temperature.

to have a hot spot design temperature of

95°C and newer 65°C rise transformers

are shown to have a hot spot design Description K1 K2 Rise which doubles ageing rate

temperature of 110°C.

The life of a transformer is often Power transformer (+55°C) 6972,15 -14,133 95°C + 5,9°C

defined as the time required for the

Power transformer (+65°C) 6972,15 -13,391 110°C + 6,4°C

mechanical strength of the insulation

material to lose 50% of its mechanical Distribution transformer (+55°C) 6328,80 -11,968 95°C + 6,6°C

strength (many other definitions are also

possible). Loss of mechanical strength Distribution transformer (+65°C) 6328,80 -11,269 110°C + 7,1°C

occurs when insulation polymers break

Table 2: Transformer aging constants for insulation equation above, determined by accelerated aging tests

down due to heat. that measure the time required for transformer insulation to lose 50% of its initial strength

energize | August 2021 | 55