Page 34 - Energize November 2022

P. 34

VIEWS AND OPINION

limits the initial production to a single model, which in turn

limits the viability of a project.

However it is unlikely that an international wind turbine

manufacturer would consider parts of a turbine to be

outsourced to local manufacture while the balance is done

overseas. The only viable solution would be to establish

a company that makes the blades and obtains the other

components from local sources.

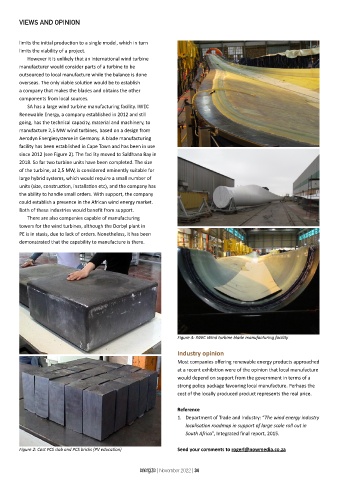

SA has a large wind turbine manufacturing facility. IWEC

Renewable Energy, a company established in 2012 and still

going, has the technical capacity, material and machinery, to

manufacture 2,5 MW wind turbines, based on a design from

Aerodyn Energiesysteme in Germany. A blade manufacturing

facility has been established in Cape Town and has been in use

since 2012 (see Figure 2). The facility moved to Saldhana Bay in

2018. So far two turbine units have been completed. The size

of the turbine, at 2,5 MW, is considered eminently suitable for

large hybrid systems, which would require a small number of

units (size, construction, installation etc), and the company has

the ability to handle small orders. With support, the company

could establish a presence in the African wind energy market.

Both of these industries would benefit from support.

There are also companies capable of manufacturing

towers for the wind turbines, although the Dorbyl plant in

PE is in stasis, due to lack of orders. Nonetheless, it has been

demonstrated that the capability to manufacture is there.

Figure 3: IWEC Wind turbine blade manufacturing facility

Industry opinion

Most companies offering renewable energy products approached

at a recent exhibition were of the opinion that local manufacture

would depend on support from the government in terms of a

strong policy package favouring local manufacture. Perhaps the

cost of the locally produced product represents the real price.

Reference

1. Department of Trade and Industry: “The wind energy industry

localisation roadmap in support of large scale roll out in

South Africa”, Integrated final report, 2015.

Figure 2: Cast PCS slab and PCS bricks (PV education) Send your comments to rogerl@nowmedia.co.za

energize | November 2022 | 34