Page 40 - Energize February 2022

P. 40

TECHNICAL

Figure 8: RDF production process (Wastebusters)

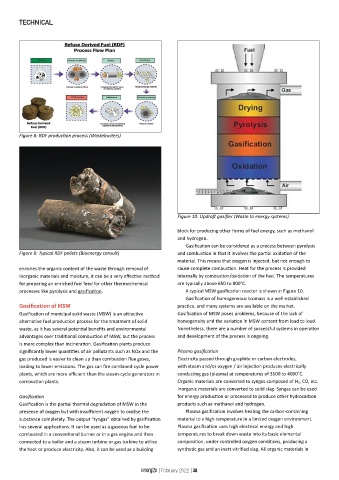

Figure 10: Updraft gasifier (Waste to energy systems)

block for producing other forms of fuel energy, such as methanol

and hydrogen.

Gasification can be considered as a process between pyrolysis

Figure 9: Typical RDF pellets (Bioenergy consult) and combustion in that it involves the partial oxidation of the

material. This means that oxygen is injected, but not enough to

enriches the organic content of the waste through removal of cause complete combustion. Heat for the process is provided

inorganic materials and moisture, it can be a very effective method internally by combustion/oxidation of the fuel. The temperatures

for preparing an enriched fuel feed for other thermochemical are typically above 650 to 800°C.

processes like pyrolysis and gasification. A typical MSW gasification reactor is shown in Figure 10.

Gasification of homogeneous biomass is a well-established

Gasification of MSW practice, and many systems are available on the market.

Gasification of municipal solid waste (MSW) is an attractive Gasification of MSW poses problems, because of the lack of

alternative fuel production process for the treatment of solid homogeneity and the variation in MSW content from load to load.

waste, as it has several potential benefits and environmental Nonetheless, there are a number of successful systems in operation

advantages over traditional combustion of MSW, but the process and development of the process is ongoing.

is more complex than incineration. Gasification plants produce

significantly lower quantities of air pollutants such as NOx and the Plasma gasification

gas produced is easier to clean up than combustion flue gases, Electricity passed through graphite or carbon electrodes,

leading to lower emissions. The gas can fire combined-cycle power with steam and/or oxygen / air injection produces electrically

plants, which are more efficient than the steam-cycle generators in conducting gas (plasma) at temperatures of 3500 to 4000˚C.

combustion plants. Organic materials are converted to syngas composed of H 2, CO, etc.

Inorganic materials are converted to solid slag. Syngas can be used

Gasification for energy production or processed to produce other hydrocarbon

Gasification is the partial thermal degradation of MSW in the products such as methanol and hydrogen.

presence of oxygen but with insufficient oxygen to oxidise the Plasma gasification involves heating the carbon-containing

substance completely. The output “syngas” obtained by gasification material to a high temperature in a limited oxygen environment.

has several applications. It can be used as a gaseous fuel to be Plasma gasification uses high electrical energy and high

combusted in a conventional burner or in a gas engine and then temperatures to break down waste into its basic elemental

connected to a boiler and a steam turbine or gas turbine to utilize composition, under controlled oxygen conditions, producing a

the heat or produce electricity. Also, it can be used as a building synthetic gas and an inert vitrified slag. All organic materials in

energize | February 2022 | 38