Page 43 - Energize February 2022

P. 43

TECHNICAL

Why specifying enclosed epoxy

insulation delivers better reliability

Information from NOJA Power

he goal of power systems engineers is to deliver reliable electricity, safely and Epoxy can be treated with additives,

sustainably, to their customers. In years past, our engineering predecessors which work to restore the surface integrity,

Twould specify the latest SF 6 gas insulated switchgear to achieve most of that goal. but these too are a finite resource. Once

Despite SF 6’s environmental damage, they would be forgiven in the context, as they had they are exhausted, the film reforms and

no alternative when choosing cost-effective switchgear. then breakdowns occur.

Today however, SF 6 insulation has been made obsolete by electrical grade solid

dielectric. This insulation is an advanced polymer that replaces the role of SF 6 in making How to avoid it

switchgear. Engineers can now specify solid dielectric as an insulation medium, but The best way is to play to the strengths of

there is a risk in specifying it alone. epoxy and to keep it away from sun and rain.

By enclosing the epoxy in stainless

The key risk is environmental factors steel and silicon, engineers mitigate the

Original epoxy insulation provides excellent insulation properties, but its resistance risk of accelerated environmental ageing

to the environment, particularly water, has been extensively researched and found of equipment.

wanting. The engineering problem is that over time, epoxy’s hydrophobicity (its water- Across the 104 countries and 75

repelling ability) degrades. This degradation accelerates in high UV, high rain, or high 000 installations of NOJA Power’s

pollution. OSM Recloser, not a single report has

While many materials scientists are working to address this shortcoming, the been made of environmentally-caused

fundamental weakness of solid dielectric insulation is environmental exposure risk. insulator failure.

Specifying solid dielectric insulation

What goes wrong enclosed in silicone and stainless steel is

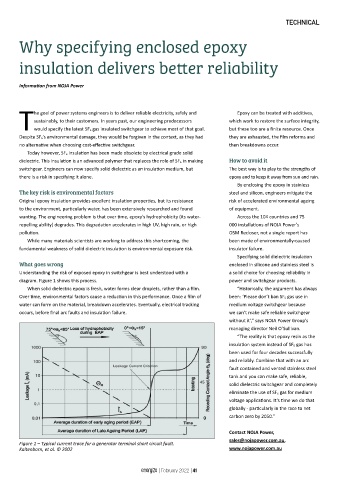

Understanding the risk of exposed epoxy in switchgear is best understood with a a solid choice for choosing reliability in

diagram. Figure 1 shows this process. power and switchgear products.

When solid dielectric epoxy is fresh, water forms clear droplets, rather than a film. “Historically, the argument has always

Over time, environmental factors cause a reduction in this performance. Once a film of been: ‘Please don’t ban SF 6 gas use in

water can form on the material, breakdown accelerates. Eventually, electrical tracking medium voltage switchgear because

occurs, before final arc faults and insulation failure. we can’t make safe reliable switchgear

without it’,” says NOJA Power Group’s

managing director Neil O’Sullivan.

“The reality is that epoxy resin as the

insulation system instead of SF 6 gas has

been used for four decades successfully

and reliably. Combine that with an arc

fault contained and vented stainless steel

tank and you can make safe, reliable,

solid dielectric switchgear and completely

eliminate the use of SF 6 gas for medium

voltage applications. It’s time we do that

globally - particularly in the race to net

carbon zero by 2050.”

Contact NOJA Power,

sales@nojapower.com.au,

Figure 1 – Typical current trace for a generator terminal short circuit fault.

Kaltenborn, et al. © 2002 www.nojapower.com.au

energize | February 2022 | 41