Page 69 - Energize July 2022

P. 69

TECHNICAL

discharges which occur but there can

be frequent small discharges. In most

cases the loads on the battery are high in

relation to the nominal capacity.

For a long time the central office was

the switching centre for transporting

all voice communication, and VLAs

were the battery of choice. With the

advent of mobile communications and

the digitizing of voice, video and data,

the telecommunications industry uses

a combination of battery types which

includes both the VLA and the VRLA cells

(individual 2 V cells and 12 V monoblocs),

and in some instances even Ni-Cds.

The important common factor in all

of the applications described above is

that these are always maintained and

operated at 100% state-of-charge (SOC).

That being the case, let us now look at

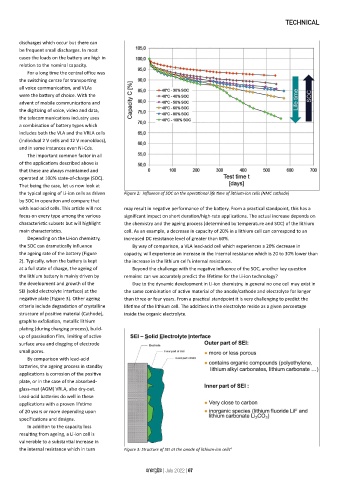

the typical ageing of Li-ion cells as driven Figure 2: Influence of SOC on the operational life time of lithium-ion cells (NMC cathode)

by SOC in operation and compare that

with lead-acid cells. This article will not may result in negative performance of the battery. From a practical standpoint, this has a

focus on every type among the various significant impact on short duration/high-rate applications. The actual increase depends on

characteristic subsets but will highlight the chemistry and the ageing process (determined by temperature and SOC) of the lithium

main characteristics. cell. As an example, a decrease in capacity of 20% in a lithium cell can correspond to an

Depending on the Li-ion chemistry, increased DC resistance level of greater than 60%.

the SOC can dramatically influence By way of comparison, a VLA lead-acid cell which experiences a 20% decrease in

the ageing rate of the battery (Figure capacity, will experience an increase in the internal resistance which is 20 to 30% lower than

2). Typically, when the battery is kept the increase in the lithium cell’s internal resistance.

at a full state of charge, the ageing of Beyond the challenge with the negative influence of the SOC, another key question

the lithium battery is mainly driven by remains: can we accurately predict the lifetime for the Li-ion technology?

the development and growth of the Due to the dynamic development in Li-ion chemistry, in general no one cell may exist in

SEI (solid electrolyte interface) at the the same combination of active material of the anode/cathode and electrolyte for longer

negative plate (Figure 3). Other ageing than three or four years. From a practical standpoint it is very challenging to predict the

criteria include degradation of crystalline lifetime of the lithium cell. The additives in the electrolyte reside as a given percentage

structure of positive material (Cathode), inside the organic electrolyte.

graphite exfoliation, metallic lithium

plating (during charging process), build-

up of passivation film, limiting of active

surface area and clogging of electrode

small pores.

By comparison with lead-acid

batteries, the ageing process in standby

applications is corrosion of the positive

plate, or in the case of the absorbed-

glass-mat (AGM) VRLA, also dry-out.

Lead-acid batteries do well in these

applications with a proven lifetime

of 20 years or more depending upon

specifications and designs.

In addition to the capacity loss

resulting from ageing, a Li-ion cell is

vulnerable to a substantial increase in

the internal resistance which in turn Figure 3: Structure of SEI at the anode of lithium-ion cells

4

energize | July 2022 | 67