Page 70 - Energize July 2022

P. 70

TECHNICAL

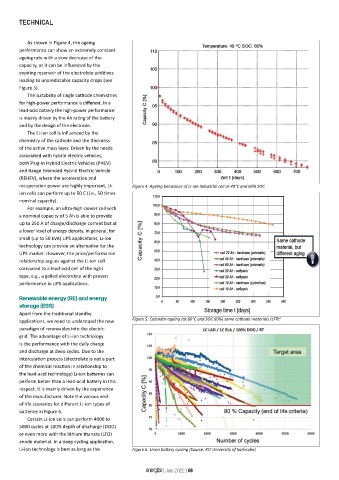

As shown in Figure 4, the ageing

performance can show an extremely constant

ageing rate with a slow decrease of the

capacity, or it can be influenced by the

expiring reservoir of the electrolyte additives

leading to unpredictable capacity drops (see

Figure 5).

The suitability of single cathode chemistries

for high-power performance is different. In a

lead-acid battery the high-power performance

is mainly driven by the Ah rating of the battery

and by the design of the electrode.

The Li-ion cell is influenced by the

chemistry of the cathode and the thickness

of the active mass layer. Driven by the needs

associated with hybrid electric vehicles,

both Plug-in Hybrid Electric Vehicles (PHEV)

and Range Extended Hybrid Electric Vehicle

(REHEV), where the acceleration and

recuperation power are highly important, Li- Figure 4: Ageing behaviour of Li-ion industrial cell at 40°C and 60% SOC

ion cells can perform up to 50 C (i.e., 50 times

nominal capacity).

For example, an ultra-high-power cell with

a nominal capacity of 5 Ah is able to provide

up to 250 A of charge/discharge current but at

a lower level of energy density. In general, for

small (up to 50 kVA) UPS applications, Li-ion

technology can provide an alternative for the

UPS market. However, the price/performance

relationship argues against the Li-ion cell

compared to a lead-acid cell of the right

type, e.g., a gelled electrolyte with proven

performance in UPS applications.

Renewable energy (RE) and energy

storage (ESS)

Apart from the traditional standby

applications, we need to understand the new Figure 5: Calendar ageing (at 60°C and SOC 60%) same cathode materials (LFP) 2

paradigm of renewables into the electric

grid. The advantage of Li-ion technology

is the performance with the daily charge

and discharge at deep cycles. Due to the

intercalation process (electrolyte is not a part

of the chemical reaction in relationship to

the lead-acid technology) Li-ion batteries can

perform better than a lead-acid battery in this

respect. It is mainly driven by the experience

of the manufacturer. Note the various end-

of-life scenarios for different Li-ion types of

batteries in Figure 6.

Certain Li-ion cells can perform 4000 to

5000 cycles at 100% depth of discharge (DOD)

or even more with the lithium titanate (LTO)

anode material. In a deep cycling application,

Li-ion technology is best as long as the Figure 6: Li-ion battery cycling (Source: KIT University of Karlsruhe)

energize | July 2022 | 68