Page 8 - Energize September 2022

P. 8

COVER STORY

Stage 1: PF analysis

An increase in power factor, measured at power frequency, was

observed on two of the three bushings (X 1 and X 3), as shown in

Table 2.

According to IEEE C57.152, the line frequency PF values for

X 1 and X 3 at 20°C exceed acceptable limits, while according to

CIGRE TB 445, the PF values of bushings X 1 and X 2 are within limits

with only bushing X 3 outside acceptable limits. Based on these

results alone, we may say that bushings X 1 and X 3 are not in good

condition, and that bushing X 3 should be further investigated as

soon as possible.

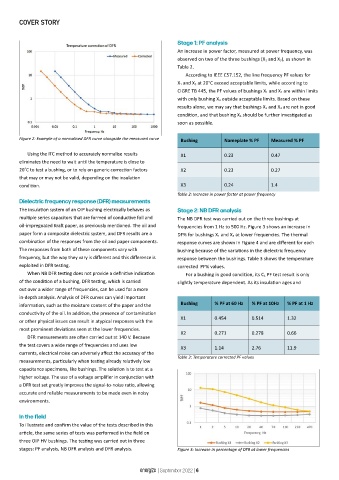

Figure 2: Example of a normalised DFR curve alongside the measured curve Bushing Nameplate % PF Measured % PF

Using the ITC method to accurately normalise results X1 0.23 0.47

eliminates the need to wait until the temperature is close to

20˚C to test a bushing, or to rely on generic correction factors X2 0.23 0.27

that may or may not be valid, depending on the insulation

condition. X3 0.24 1.4

Table 2: Increase in power factor at power frequency

Dielectric frequency response (DFR) measurements

The insulation system of an OIP bushing electrically behaves as Stage 2: NB DFR analysis

multiple series capacitors that are formed of conductive foil and The NB DFR test was carried out on the three bushings at

oil-impregnated Kraft paper, as previously mentioned. The oil and frequencies from 1 Hz to 500 Hz. Figure 3 shows an increase in

paper form a composite dielectric system, and DFR results are a DF% for bushings X 1 and X 3 at lower frequencies. The thermal

combination of the responses from the oil and paper components. response curves are shown in Figure 4 and are different for each

The responses from both of these components vary with bushing because of the variations in the dielectric frequency

frequency, but the way they vary is different and this difference is response between the bushings. Table 3 shows the temperature

exploited in DFR testing. corrected PF% values.

When NB DFR testing does not provide a definitive indication For a bushing in good condition, its C 1 PF test result is only

of the condition of a bushing, DFR testing, which is carried slightly temperature dependent. As its insulation ages and

out over a wider range of frequencies, can be used for a more

in-depth analysis. Analysis of DFR curves can yield important

information, such as the moisture content of the paper and the Bushing % PF at 60 Hz % PF at 10Hz % PF at 1 Hz

conductivity of the oil. In addition, the presence of contamination

X1 0.454 0.514 1.32

or other physical issues can result in atypical responses with the

most prominent deviations seen at the lower frequencies. X2 0.271 0.278 0.66

DFR measurements are often carried out at 140 V. Because

the test covers a wide range of frequencies and uses low X3 1.14 2.76 11.9

currents, electrical noise can adversely affect the accuracy of the

measurements, particularly when testing already relatively low Table 3: Temperature corrected PF values

capacitance specimens, like bushings. The solution is to test at a

higher voltage. The use of a voltage amplifier in conjunction with

a DFR test set greatly improves the signal-to-noise ratio, allowing

accurate and reliable measurements to be made even in noisy

environments.

In the field

To illustrate and confirm the value of the tests described in this

article, the same series of tests was performed in the field on

three OIP HV bushings. The testing was carried out in three

stages: PF analysis, NB DFR analysis and DFR analysis. Figure 3: Increase in percentage of DFR at lower frequencies

energize | September 2022 | 6