Page 9 - Energize September 2022

P. 9

COVER STORY

Bushing condition % PF at 20˚C and 1 Hz

Good 0.2 – 0.5

Moderate 0.5 – 0.75

Severe 0.15 – 0.2 and 0.75 – 1.25

Extreme <0.15 and >1.25

Table 4: Megger proposed PF limits at 1 Hz

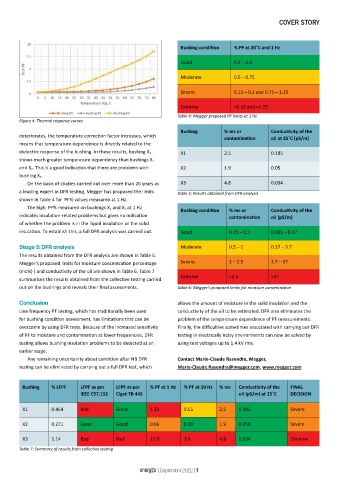

Figure 4: Thermal response curves

Bushing % mc or Conductivity of the

deteriorates, the temperature correction factor increases, which contamination oil at 25˚C (pS/m)

means that temperature dependence is directly related to the

dielectric response of the bushing. In these results, bushing X 3 X1 2.5 0.185

shows much greater temperature dependency than bushings X 1

and X 2. This is a good indication that there are problems with X2 1.9 0.05

bushing X 3.

On the basis of studies carried out over more than 20 years as X3 4.8 0.034

a leading expert in DFR testing, Megger has proposed the limits Table 5: Results obtained from DFR analysis

shown in Table 4 for PF% values measured at 1 Hz.

The high PF% measured on bushings X 1 and X 3 at 1 Hz Bushing condition % mc or Conductivity of the

indicates insulation-related problems but gives no indication contamination oil (pS/m)

of whether the problem is in the liquid insulation or the solid

insulation. To establish this, a full DFR analysis was carried out. Good 0.15 – 0.5 0.001 – 0.37

Stage 3: DFR analysis Moderate 0.5 – 1 0.37 – 3.7

The results obtained from the DFR analysis are shown in Table 5.

Megger’s proposed limits for moisture concentration percentage Severe 1 – 2.5 3.7 – 37

(mc%) ) and conductivity of the oil are shown in Table 6. Table 7

summarises the results obtained from the collective testing carried Extreme >2.5 >37

out on the bushings and reveals their final assessments. Table 6: Megger’s proposed limits for moisture concentration

Conclusion allows the amount of moisture in the solid insulation and the

Line frequency PF testing, which has traditionally been used conductivity of the oil to be estimated. DFR also eliminates the

for bushing condition assessment, has limitations that can be problem of the temperature dependence of PF measurements.

overcome by using DFR tests. Because of the increased sensitivity Finally, the difficulties sometimes associated with carrying out DFR

of PF to moisture and contamination at lower frequencies, DFR testing in electrically noisy environments can now be solved by

testing allows bushing insulation problems to be detected at an using test voltages up to 1,4 kV rms.

earlier stage.

Any remaining uncertainty about condition after NB DFR Contact Marie-Claude Rasendra, Megger,

testing can be eliminated by carrying out a full DFR test, which Marie-Claude.Rasendra@megger.com, www.megger.com

Bushing % LFPF LFPF as per LFPF at per % PF at 1 Hz % PF at 10 Hz % mc Conductivity of the FINAL

IEEE C57.152 Cigré TB 445 oil (pS/m) at 25˚C DECISION

X1 0.454 Bad Good 1.32 0.55 2.5 0.185 Severe

X2 0.271 Good Good 0.66 0.29 1.9 0.058 Severe

X3 1.14 Bad Bad 11.9 3.6 4.8 0.034 Extreme

Table 7: Summary of results from collective testing

energize | September 2022 | 7