Page 21 - Issue 4 2023

P. 21

TECHNICAL

area of concern with the move to high string voltages (>1000 VDC). PID is generally occurs during operation in the

caused by the difference in potential between the cell and other parts of the system, daytime. However, if the panels have

notably the metal frame which is generally at earth potential. Often, PID is related to been subject to PID for a long time,

a negative voltage potential to earth, with the more negative panel being the panel at the regeneration will last half of the

most risk. The PID effect is caused by the system’s exposure to an external potential. degradation period.

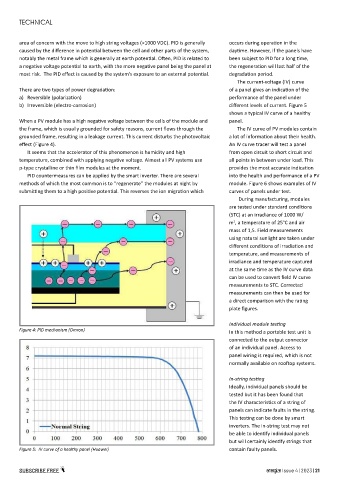

The current-voltage (IV) curve

There are two types of power degradation: of a panel gives an indication of the

a) Reversible (polarization) performance of the panel under

b) Irreversible (electro-corrosion) different levels of current. Figure 5

shows a typical IV curve of a healthy

When a PV module has a high negative voltage between the cells of the module and panel.

the frame, which is usually grounded for safety reasons, current flows through the The IV curve of PV modules contain

grounded frame, resulting in a leakage current. This current disturbs the photovoltaic a lot of information about their health.

effect (Figure 4). An IV curve tracer will test a panel

It seems that the accelerator of this phenomenon is humidity and high from open circuit to short circuit and

temperature, combined with applying negative voltage. Almost all PV systems use all points in between under load. This

p-type crystalline or thin film modules at the moment. provides the most accurate indication

PID countermeasures can be applied by the smart inverter. There are several into the health and performance of a PV

methods of which the most common is to “regenerate” the modules at night by module. Figure 6 shows examples of IV

submitting them to a high positive potential. This reverses the ion migration which curves of panels under test.

During manufacturing, modules

are tested under standard conditions

(STC) at an irradiance of 1000 W/

m , a temperature of 25°C and air

2

mass of 1,5. Field measurements

using natural sunlight are taken under

different conditions of irradiation and

temperature, and measurements of

irradiance and temperature captured

at the same time as the IV curve data

can be used to convert field IV curve

measurements to STC. Corrected

measurements can then be used for

a direct comparison with the rating

plate figures.

Individual module testing

Figure 4: PID mechanism (Omron) In this method a portable test unit is

connected to the output connector

of an individual panel. Access to

panel wiring is required, which is not

normally available on rooftop systems.

In-string testing

Ideally, individual panels should be

tested but it has been found that

the IV characteristics of a string of

panels can indicate faults in the string.

This testing can be done by smart

inverters. The in-string test may not

be able to identify individual panels

but will certainly identify strings that

Figure 5: IV curve of a healthy panel (Huawei) contain faulty panels.

SUBSCRIBE FREE energize Issue 4 | 2023 | 21