Page 31 - Energize January 2021

P. 31

TECHNICAL

Developments in PV module

technology initiates new high-power

technology platform

Information from Trina Solar

In May 2020, Trina Solar published a technology white paper outlining a high-output and high-efficiency

PV module called Vertex. According to the company, the maximum output and efficiency of the Vertex

module can exceed 500 W and 21% efficiency.

ccording to measurement data cryogenic laser technology are both employed by Trina Solar to avoid cell breakage and

issued by TÜV Rheinland in 2020, fissure risks on the basis of thermal expansion and contraction.

the output of the Vertex can At the same time, the Vertex has also come up with layout design innovations. Its 5 x 30

Areach up to 515,8 W. Trina Solar layout is different from the traditional 6 x 20 and 6 x 24 layouts found in 158 mm series

has already ramped production on the pilot modules. It is common practice in power plant design and construction to accept the

line and started shipment of the Vertex. matching module size for conventional wafers. If conventional layouts had been used, the

size and weight of the Vertex would increase by approximately 40% or more.

Innovation is the secret to ultra-high Starting from realities both upstream and downstream, the 5 x 30 layout and high-

power module technology density technology employed by the Vertex have made its size almost the same as that of a

Explaining Trina Solar's decision to use regular 166 mm series module. The Vertex is more compatible with downstream installation

210mm for the 500 W-plus PV module designs, thus avoiding additional cost increase and glass furnace limitations.

era, Rongfang Yin, vice general manager

and executive vice president of Trina Reliability and compatibility: all in one

Solar, says 210 mm is almost the upper The Vertex released by Trina Solar includes glass-backsheet and glass-glass bifacial

limit for wafers in the PV industry which modules, which are suitable for large ground-mount plants and commercial and industrial

is unlikely to change for at least five to rooftop projects. These application scenarios are highly demanding on module reliability.

ten years. It will help standardise both The company has made great efforts in mechanical load calculation and hot spot

PV module sizes and downstream PV prevention to guarantee module reliability and high-power output. Through finite element

system designs, he added.

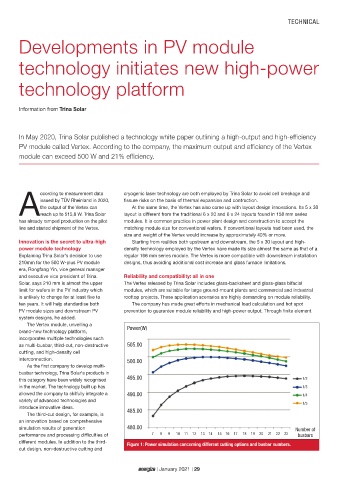

The Vertex module, unveiling a

Power(W)

brand-new technology platform,

incorporates multiple technologies such

as multi-busbar, third-cut, non-destructive 505.00

cutting, and high-density cell

interconnection.

500.00

As the first company to develop multi-

busbar technology, Trina Solar’s products in

495.00 1/2

this category have been widely recognised

in the market. The technology built up has 1/3

allowed the company to skilfully integrate a 490.00 1/4

variety of advanced technologies and

1/5

introduce innovative ideas.

485.00

The third-cut design, for example, is

an innovation based on comprehensive

simulation results of generation 480.00 Number of

performance and processing difficulties of 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 busbars

different modules. In addition to the third-

Figure 1: Power simulation concerning different cutting options and busbar numbers.

cut design, non-destructive cutting and

energize | January 2021 | 29