Page 32 - Energize January 2021

P. 32

TECHNICAL

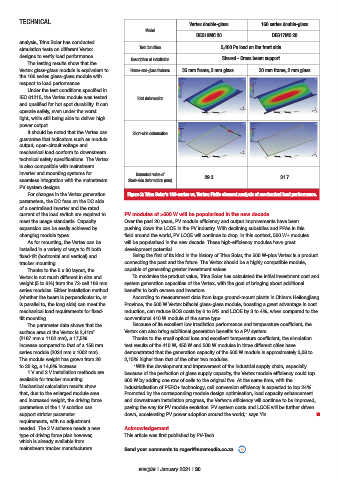

Vertex double-glass 166 series double-glass

Model

DEG18MC.20 DEG17MC.20

analysis, Trina Solar has conducted

simulation tests on different Vertex Test Condition 5,400 Pa load on the front side

designs to verify load performance.

Description of installation Shared - Cross beam support

The testing results show that the

Vertex glass-glass module is equivalent to Frame-and-glass features 35 mm frame, 2 mm glass 30 mm frame, 2 mm glass

the 166 series glass-glass module with

respect to load performance.

Under the test conditions specified in

IEC 61215, the Vertex module was tested Total deformation

and qualified for hot spot durability. It can

operate safely, even under the worst

light, while still being able to deliver high

power output.

It should be noted that the Vertex can Short-side deformation

guarantee that indicators such as module

output, open-circuit voltage and

mechanical load conform to downstream

technical safety specifications. The Vertex

is also compatible with mainstream

inverter and mounting systems for Numerical value of

seamless integration with the mainstream Short-side deformation (mm) 29.3 31.7

PV system designs.

For changes in the Vertex generation Figure 2: Trina Solar's 166-series vs. Vertex: Finite element analysis of mechanical load performance.

parameters, the DC fuse on the DC side

of a centralised inverter and the rated

current of the load switch are required to PV modules of >500 W will be popularised in the new decade

meet the usage standards. Capacity Over the past 20 years, PV module efficiency and output improvements have been

expansion can be easily achieved by pushing down the LCOE in the PV industry. With declining subsidies and PPAs in this

changing module types. field around the world, PV LCOE will continue to drop. In this context, 500 W+ modules

As for mounting, the Vertex can be will be popularised in the new decade. These high-efficiency modules have great

installed in a variety of ways to fit both development potential.

fixed-tilt (horizontal and vertical) and Being the first of its kind in the history of Trina Solar, the 500 W-plus Vertex is a product

tracker mounting. connecting the past and the future. The Vertex should be a highly compatible module,

Thanks to the 5 x 30 layout, the capable of generating greater investment values.

Vertex is not much different in size and To maximise the product value, Trina Solar has calculated the initial investment cost and

weight (5 to 6%) from the 72-cell 166 mm system generation capacities of the Vertex, with the goal of bringing about additional

series modules. Either installation method benefits to both owners and investors.

(whether the beam is perpendicular to, or According to measurement data from large ground-mount plants in China’s Heilongjiang

is parallel to, the long side) can meet the Province, the 500 W Vertex bifacial glass-glass module, boasting a great advantage in cost

mechanical load requirements for fixed- reduction, can reduce BOS costs by 6 to 8% and LCOE by 3 to 4%, when compared to the

tilt mounting. conventional 410 W module of the same type.

The parameter data shows that the Because of its excellent low irradiation performance and temperature coefficient, the

surface area of the Vertex is 2,41m 2 Vertex can also bring additional generation benefits to a PV system.

(2187 mm x 1102 mm), a 17,5% Thanks to the small optical loss and excellent temperature coefficient, the simulation

increase compared to that of a 158 mm test results of the 410 W, 450 W and 500 W modules in three different cities have

series module (2024 mm x 1002 mm). demonstrated that the generation capacity of the 500 W module is approximately 0,08 to

The module weight has grown from 26 2,15% higher than that of the other two modules.

to 30 kg, a 14,6% increase. “With the development and improvement of the industrial supply chain, especially

1 V and 2 V installation methods are because of the perfection of glass supply capacity, the Vertex module efficiency could top

available for tracker mounting. 600 W by adding one row of cells to the original five. At the same time, with the

Mechanical calculation results show industrialisation of PERC+ technology, cell conversion efficiency is expected to top 24%.

that, due to the enlarged module area Promoted by the corresponding module design optimisation, load capacity enhancement

and increased weight, the driving force and downstream installation progress, the Vertex's efficiency will continue to be improved,

parameters of the 1 V solution can paving the way for PV module evolution. PV system costs and LCOE will be further driven

support stricter parameter down, accelerating PV power adoption around the world,” says Yin. n

requirements, with no adjustment

needed. The 2 V scheme needs a new Acknowledgement

type of driving force plan however, This article was first published by PV-Tech.

which is already available from

mainstream tracker manufacturers. Send your comments to rogerl@nowmedia.co.za

energize | January 2021 | 30