Page 35 - Energize February 2021

P. 35

TECHNICAL

Food waste to energy: the final link

in the chain to zero waste

by Mike Rycroft, Now Media

The production of energy from organic waste is a well-established process. Biodigestors which recover

energy from animal, human, agricultural, and industrial waste are common. Recent developments have

focused on biodigestion as a means of disposing of the organic portion of municipal or food waste, with

electricity being the end product.

he main driver behind this development is concern over bioconversion technologies, such as anaerobic digestion, more

the amount of organic waste being disposed of in landfills. suitable than thermochemical conversion technologies, such as

The recycling and separation of municipal waste leads to combustion and gasification. 4

Tthe final remnant of waste, comprising mainly food, going It is estimated that a third of the food produced in South Africa

into landfills. The proportion of food entering the waste stream goes to waste. This amounts to some 10-million tonnes of organic

1

depends on socio-economic, geographic, and other factors, but it waste annually, which mostly finds its way into landfills. These

has been estimated that anything from 25 to 65% of the municipal losses occur at all stages of production, from pre-harvest on the

1

solid waste (MSW) stream consists of food material. In the light of farm through to post-harvest losses during processing,

the rapidly rising costs associated with energy supply and waste distribution, retailing and consumption. Wastage occurs at all

disposal, and increasing public concerns with environmental points along the chain, but mainly at production and distribution. 1

quality degradation, conversion of food wastes to energy is By far the largest proportion of this material is generated at the

becoming a more economically viable practice. 4 point of distribution or consumption, in the home or in hospitality

Recent developments in anaerobic digestors allow onsite venues such as hotels, cafeterias, canteens and restaurants.

production of electricity from small quantities of food waste, Food waste, which consists of proteins, fats, carbohydrates,

making it possible to use this process for shopping malls, and essential elements, is easily biodegradable and has a high

industrial complexes, hospitals and other small to medium sized biochemical methane potential (BMP). Once completely

plants where food is sold, processed or consumed. The relatively biodigested, food waste produces some 350 - 450 m3 of

high moisture content of food waste (74 to 90%) makes gas/tonne. The food wasted in South Africa has therefore the

potential to produce more than 3500 000 000 m3 of methane

gas/year. This has an energy potential of approximately 35 000 000

000 kWh (35 TWh), or approximately 100 GWh/day. Assuming an

electrical conversion efficiency of 30% this could generate 30

GWh of electricity per day, which is approximately equal to 1,2 GW

of continuous generation, approximately 2,6% of South Africa’s

total generation capacity.

Food waste composition is not homogeneous, and this affects

the gas production rate and effectiveness of the digestor and will

vary from site to site. Food waste comprises unprocessed

vegetables, fruit and grains, cooked vegetables and fruit, grain,

processed grains (such as bread, pasta, bakery products), sugars,

raw and cooked protein (meat, eggs) and dairy products. The mix

will vary according to location and could also vary seasonally.

Figure 2 gives the breakdown of a municipal food waste sample.

Municipal solid waste collection

Biodigestion of food waste requires separation of food waste from

other waste, either at source or at the waste site. Separation at

site, to allow recycling and recovery of waste material, is a

common practice. Separation at the source leaves the balance of

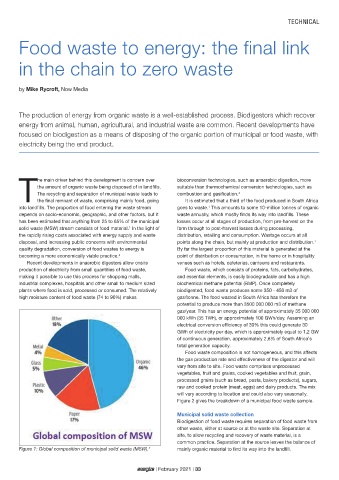

Figure 1: Global composition of municipal solid waste (MSW). 2 mainly organic material to find its way into the landfill.

energize | February 2021 | 33