Page 53 - Energize October 2021

P. 53

TECHNICAL

Figure 4: Ripple for each tap transition for all 3 phases

Figure 5

by the ‘ripple’, which expresses the maximum amount that the DC

current decreases as a percentage of the test current. The ripple is

normally plotted for all phases and taps as presented in Figure 4.

From Figure 4 the following is observed:

• The ripples of phases A and C practically overlap each other.

• The ripple is higher for Phase B and varies much more than the

ripples in phases A and C do, the latter which lend to nearly flat lines.

• The ripple graph from phase B may be different compared to the

graphs of phase A and/or C due to different induction.

In this case, the difference in ripples between phases combined with

the variance of ripples within Phase B indicate a problem for Phase B.

DRM analysis provides even more insight than comes from measuring

the ripple alone.

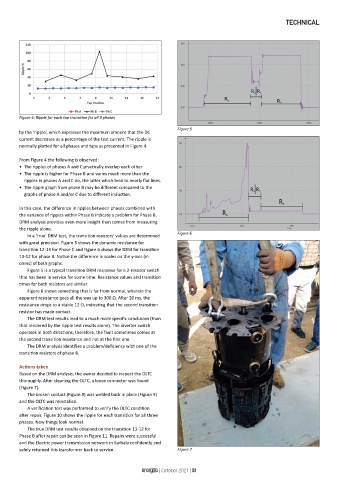

In a ‘true’ DRM test, the transition resistors’ values are determined Figure 6

with great precision. Figure 5 shows the dynamic resistance for

transition 12-13 for Phase C and Figure 6 shows the DRM for transition

13-12 for phase B. Notice the difference in scales on the y-axis (in

ohms) of both graphs.

Figure 5 is a typical transition DRM response for a 2-resistor switch

that has been in service for some time. Resistance values and transition

times for both resistors are similar.

Figure 6 shows something that is far from normal, wherein the

apparent resistance goes all the way up to 300 Ω. After 20 ms, the

resistance drops to a stable 12 Ω, indicating that the second transition

resistor has made contact.

The DRM test results lead to a much more specific conclusion (than

that rendered by the ripple test results alone). The diverter switch

operates in both directions; therefore, the fault sometimes comes at

the second transition resistance and not at the first one.

The DRM analysis identifies a problem/deficiency with one of the

transition resistors of phase B.

Actions taken

Based on the DRM analysis, the owner decided to inspect the OLTC

thoroughly. After cleaning the OLTC, a loose connector was found

(Figure 7).

The broken contact (Figure 8) was welded back in place (Figure 9)

and the OLTC was reinstalled.

A verification test was performed to verify the OLTC condition

after repair. Figure 10 shows the ripple for each transition for all three

phases. Now things look normal.

The true DRM test results obtained on the transition 13-12 for

Phase B after repair can be seen in Figure 11. Repairs were successful

and the Electric power transmission network in Karbala confidently and

safely returned this transformer back to service. Figure 7

energize | October 2021 | 51