Page 52 - Energize January 2022

P. 52

TECHNICAL

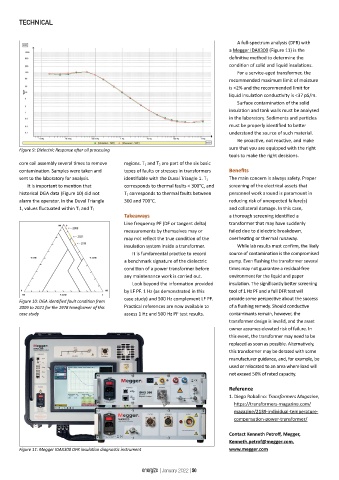

A full-spectrum analysis (DFR) with

a Megger IDAX300 (Figure 11) is the

definitive method to determine the

condition of solid and liquid insulations.

For a service-aged transformer, the

recommended maximum limit of moisture

is <2% and the recommended limit for

liquid insulation conductivity is <37 pS/m.

Surface contamination of the solid

insulation and tank walls must be analysed

in the laboratory. Sediments and particles

must be properly identified to better

understand the source of such material.

Be proactive, not reactive, and make

Figure 9: Dielectric Response after oil processing sure that you are equipped with the right

tools to make the right decisions.

core coil assembly several times to remove regions. T 1 and T 2 are part of the six basic

contamination. Samples were taken and types of faults or stresses in transformers Benefits

sent to the laboratory for analysis. identifiable with the Duval Triangle 1. T 1 The main concern is always safety. Proper

It is important to mention that corresponds to thermal faults < 300°C, and screening of the electrical assets that

historical DGA data (Figure 10) did not T 2 corresponds to thermal faults between personnel work around is paramount in

alarm the operator. In the Duval Triangle 300 and 700°C. reducing risk of unexpected failure(s)

1, values fluctuated within T 1 and T 2 and collateral damage. In this case,

Takeaways a thorough screening identified a

Line frequency PF (DF or tangent delta) transformer that may have suddenly

measurements by themselves may or failed due to dielectric breakdown,

may not reflect the true condition of the overheating or thermal runaway.

insulation system inside a transformer. While lab results must confirm, the likely

It is fundamental practice to record source of contamination is the compromised

a benchmark signature of the dielectric pump. Even flushing the transformer several

condition of a power transformer before times may not guarantee a residual-free

any maintenance work is carried out. environment for the liquid and paper

Look beyond the information provided insulation. The significantly better screening

by LF PF. 1 Hz (as demonstrated in this tool of 1 Hz PF and a full DFR test will

case study) and 500 Hz complement LF PF. provide some perspective about the success

Figure 10: DGA identified fault condition from

2009 to 2021 for the 1978 transformer of this Practical references are now available to of a flushing remedy. Should conductive

case study assess 1 Hz and 500 Hz PF test results. contaminants remain, however, the

transformer design is invalid, and the asset

owner assumes elevated risk of failure. In

this event, the transformer may need to be

replaced as soon as possible. Alternatively,

this transformer may be derated with some

manufacturer guidance, and, for example, be

used or relocated to an area where load will

not exceed 50% of rated capacity.

Reference

1. Diego Robalino: Transformers Magazine,

https://transformers-magazine.com/

magazine/2139-individual-temperature-

compensation-power-transformer/

Contact Kenneth Petroff, Megger,

Kenneth.petrof@megger.com,

Figure 11: Megger IDAX300 DFR insulation diagnostic instrument www.megger.com

energize | January 2022 | 50