Page 64 - Energize April 2022

P. 64

TECHNICAL

Single units of either technology lose efficiency when

operating at partial load and also exhibit a minimum load

below which they cannot operate within allowed limits of

performance. A technical constraint for partial load operation

of gas turbine power plants is the minimum environmental

load, also called the minimum emissions-compliant load. This

is the lowest output at which the generating unit can operate

and still meet environmental limits for nitrous oxides (NOx) and

carbon monoxide (CO) emissions. The minimum environmental

load for most gas turbines is about 50% of full output because

operation at lower loads can result in potential emissions-permit

exceedances. In combined cycle plants, the gas turbine outlet

temperature must also be kept high to produce sufficient steam

to power the steam turbine.

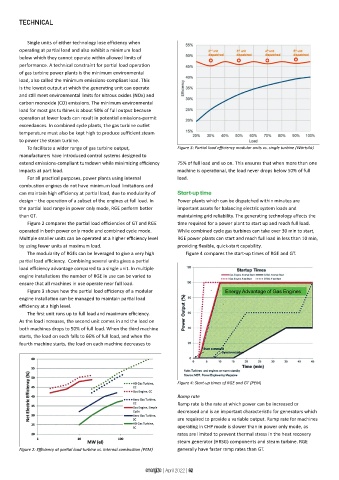

To facilitate a wider range of gas turbine output, Figure 3: Partial load efficiency modular units vs. single turbine (Wärtsilä)

manufacturers have introduced control systems designed to

extend emissions-compliant turndown while minimizing efficiency 75% of full load and so on. This ensures that when more than one

impacts at part load. machine is operational, the load never drops below 50% of full

For all practical purposes, power plants using internal load.

combustion engines do not have minimum load limitations and

can maintain high efficiency at partial load, due to modularity of Start-up time

design – the operation of a subset of the engines at full load. In Power plants which can be dispatched within minutes are

the partial load range in power only mode, RGE perform better important assets for balancing electric system loads and

than GT. maintaining grid reliability. The generating technology affects the

Figure 2 compares the partial load efficiencies of GT and RGE time required for a power plant to start up and reach full load.

operated in both power only mode and combined cycle mode. While combined cycle gas turbines can take over 30 min to start,

Multiple smaller units can be operated at a higher efficiency level RGE power plants can start and reach full load in less than 10 min,

by using fewer units at maximum load. providing flexible, quick-start capability.

The modularity of RGEs can be leveraged to give a very high Figure 4 compares the start-up times of RGE and GT.

partial load efficiency. Combining several units gives a partial

load efficiency advantage compared to a single unit. In multiple

engine installations the number of RGE in use can be varied to

ensure that all machines in use operate near full load.

Figure 3 shows how the partial load efficiency of a modular

engine installation can be managed to maintain partial load

efficiency at a high level.

The first unit runs up to full load and maximum efficiency.

As the load increases, the second unit comes in and the load on

both machines drops to 50% of full load. When the third machine

starts, the load on each falls to 66% of full load, and when the

fourth machine starts, the load on each machine decreases to

Figure 4: Start-up times of RGE and GT (PEM)

Ramp rate

Ramp rate is the rate at which power can be increased or

decreased and is an important characteristic for generators which

are required to provide a variable output. Ramp rate for machines

operating in CHP mode is slower than in power only mode, as

rates are limited to prevent thermal stress in the heat recovery

steam generator (HRSG) components and steam turbine. RGE

Figure 2: Efficiency at partial load turbine vs. internal combustion (PEM) generally have faster ramp rates than GT.

energize | April 2022 | 62