Page 67 - Energize April 2022

P. 67

TECHNICAL

An alternative emerges

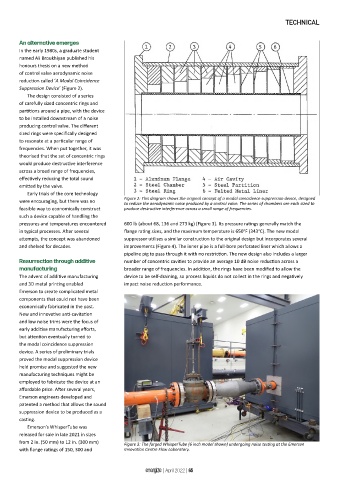

In the early 1980s, a graduate student

named Ali Broukhiyan published his

honours thesis on a new method

of control valve aerodynamic noise

reduction called ‘A Modal Coincidence

Suppression Device’ (Figure 2).

The design consisted of a series

of carefully sized concentric rings and

partitions around a pipe, with the device

to be installed downstream of a noise

producing control valve. The different

sized rings were specifically designed

to resonate at a particular range of

frequencies. When put together, it was

theorised that the set of concentric rings

would produce destructive interference

across a broad range of frequencies,

effectively reducing the total sound

emitted by the valve.

Early trials of the core technology

Figure 2: This diagram shows the original concept of a modal coincidence suppression device, designed

were encouraging, but there was no to reduce the aerodynamic noise produced by a control valve. The series of chambers are each sized to

feasible way to economically construct produce destructive interference across a small range of frequencies.

such a device capable of handling the

pressures and temperatures encountered 600 lb (about 68, 136 and 273 kg) (Figure 3). Its pressure ratings generally match the

in typical processes. After several flange rating sizes, and the maximum temperature is 650°F (343°C). The new modal

attempts, the concept was abandoned suppressor utilises a similar construction to the original design but incorporates several

and shelved for decades. improvements (Figure 4). The inner pipe is a full-bore perforated liner which allows a

pipeline pig to pass through it with no restriction. The new design also includes a larger

Resurrection through additive number of concentric cavities to provide an average 10 dB noise reduction across a

manufacturing broader range of frequencies. In addition, the rings have been modified to allow the

The advent of additive manufacturing device to be self-draining, so process liquids do not collect in the rings and negatively

and 3D metal printing enabled impact noise reduction performance.

Emerson to create complicated metal

components that could not have been

economically fabricated in the past.

New and innovative anti-cavitation

and low noise trims were the focus of

early additive manufacturing efforts,

but attention eventually turned to

the modal coincidence suppression

device. A series of preliminary trials

proved the modal suppression device

held promise and suggested the new

manufacturing techniques might be

employed to fabricate the device at an

affordable price. After several years,

Emerson engineers developed and

patented a method that allows the sound

suppression device to be produced as a

casting.

Emerson’s WhisperTube was

released for sale in late 2021 in sizes

from 2 in. (50 mm) to 12 in. (300 mm) Figure 3: The forged WhisperTube (6 inch model shown) undergoing noise testing at the Emerson

with flange ratings of 150, 300 and Innovation Centre Flow Laboratory.

energize | April 2022 | 65