Page 63 - Energize April 2022

P. 63

TECHNICAL

partial load operation and redundancy. In addition, capacity can uses 20 Jenbacher J920 FleXtra gas engines, each with an

easily be extended by adding extra units. output of up to 10,4 MW , and the Aliaga Cakmaktepe power

1

Interconnecting different modules offers flexibility of plant project in Turkey that uses 28 Wärtsilä 20V34SG GEs in

design to meet a variety of project needs. Generating units a combined cycle configuration to produce 270 MW of peak

are incrementally sized, allowing the design of a wide range of power. 5

plant capacities and fuel options, including multi-fuel use. The There are also numerous installations in the 10 to 100 MW

control systems and interfaces between modules are designed to range. The largest gas engine generator installation is of the

accommodate fuel selection, expected operations and emissions order of 600 MW. Figures 1a and 1b show typical installations.

permit limits. Combustion engines are ideally suited to modular

use, as sets of 4 to 30 MW engine units can provide a range of

incremental part-load power without sacrificing efficiency.

For example, a power plant which has 20 engine sets, each

sized at approximately 10 MW, could deliver a range of output

from just a few MW to close to 200 MW. By operating just a subset

of the engines at full load to produce the desired output, high

efficiency is maintained. The startup time for combustion engines

is quick (within minutes), so a power plant could quickly adjust to

changes in load by bringing additional engine sets online.

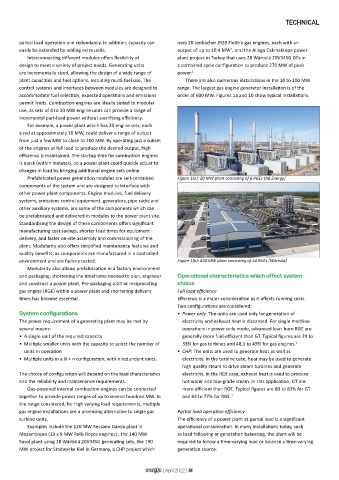

Prefabricated power generation modules are self-contained Figure 1(a): 20 MW plant consisting of 6 RGEs (AB Energy)

components of the system and are designed to interface with

other power plant components. Engine modules, fuel delivery

systems, emissions control equipment, generators, pipe racks and

other auxiliary systems, are some of the components which can

be prefabricated and delivered in modules to the power plant site.

Standardising the design of these components offers significant

manufacturing cost savings, shorter lead times for equipment

delivery, and faster on-site assembly and commissioning of the

plant. Modularity also offers simplified maintenance features and

quality benefits, as components are manufactured in a controlled

environment and are factory tested. Figure 1(b): 430 MW plant consisting of 24 RGEs (Wärtsilä)

Modularity also allows prefabrication in a factory environment

and packaging, shortening the timeframe needed to plan, engineer Operational characteristics which affect system

and construct a power plant. Pre-packaging a GT or reciprocating choice

gas engine (RGE) within a power plant and shortening delivery Full load efficiency

times has become essential. Efficiency is a major consideration as it affects running costs.

Two configurations are considered:

System configurations • Power only: The units are used only for generation of

The power requirement of a generating plant may be met by electricity and exhaust heat is discarded. For single machine

several means: operations in power only mode, advanced lean-burn RGE are

• A single unit of the required capacity generally more fuel-efficient than GT. Typical figures are 29 to

• Multiple smaller units with the capacity to select the number of 33% for gas turbines and 48,5 to 49% for gas engines. 1

units in operation • CHP: The units are used to generate heat as well as

• Multiple units in a N + n configuration, with n redundant units. electricity. In the turbine case, heat may be used to generate

high quality steam to drive steam turbines and generate

The choice of configuration will depend on the load characteristics electricity. In the RGE case, exhaust heat is used to produce

and the reliability and maintenance requirements. hot water and low-grade steam. In this application, GT are

Gas-powered internal combustion engines can be connected more efficient than RGE. Typical figures are 80 to 83% for GT

together to provide power ranges of up to several hundred MW. In and 63 to 77% for RGE. 1

the range considered, for high varying load requirements, multiple

gas engine installations are a promising alternative to single gas Partial load operation efficiency

turbine units. The efficiency of a power plant at partial load is a significant

Examples include the 120 MW Ressano Garcia plant in operational consideration. In many installations today, such

Mozambique (13 x 9 MW Rolls Royce engines) , the 140 MW as load following or generation balancing, the plant will be

Sasol plant using 18 Wärtsilä 20V34SG generating sets, the 190 required to follow a time-varying load or balance a time-varying

MW project for Stadwerke Kiel in Germany, a CHP project which generation source.

energize | April 2022 | 61