Page 61 - Energize May 2022

P. 61

TECHNICAL

Winding resistance results are

usually interpreted based on comparing

measurements made separately on each

phase of a wye-connected winding or

between pairs of terminals on a delta-

connected winding. A comparison may

also be made with original data measured

in the factory.

A measurement is deemed

acceptable, and no further investigation

is needed, if the individual phase

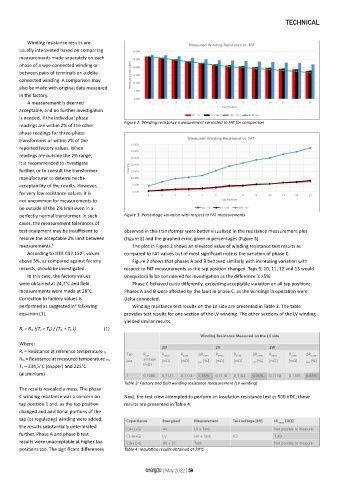

readings are within 2% of the other Figure 2: Winding resistance measurement corrected to FAT for comparison

phase readings for three-phase

transformers or within 2% of the

reported factory values. When

readings are outside the 2% range,

it is recommended to investigate

further, or to consult the transformer

manufacturer to determine the

acceptability of the results. However,

for very low resistance values, it is

not uncommon for measurements to

be outside of the 2% limit even in a

perfectly normal transformer. In such Figure 3: Percentage variation with respect to FAT measurements

cases, the measurement tolerances of

test equipment may be insufficient to observed in this transformer were better visualised in the resistance measurement plot

resolve the acceptable 2% limit between (Figure 2) and the graphed error, given in percentages (Figure 3).

measurements. 1 The plot in Figure 2 shows an elevated value of winding resistance test results as

According to IEEE C57.152 , values compared to FAT values but of most significant note is the variation of phase C.

2

above 5%, as compared against factory Figure 2 shows that phases A and B behaved similarly with increasing variation with

records, should be investigated. respect to FAT measurements as the tap position changed. Taps 9, 10, 11, 12 and 13 would

In this case, the factory values unequivocally be considered for investigation as the difference is >5%.

were obtained at 24,7°C and field Phase C behaved quite differently, exceeding acceptable variation on all tap positions.

measurements were made at 28°C. Phases A and B were affected by the fault in phase C, as the windings in operation were

Correction to factory values is Delta connected.

performed as suggested in following Winding resistance test results on the LV side are presented in Table 3. The table

2

equation (1). provides test results for one section of the LV winding. The other sections of the LV winding

yielded similar results.

R s = R m ((T s + T k) / (T m + T k )) (1)

Where:

R s = Resistance at reference temperature Ts

R m = Resistance at measured temperature Tm

T k – 234,5°C (copper) and 225°C

(aluminium)

Table 3: Factory and field winding resistance measurement (LV winding)

The results revealed a mess. The phase

C winding resistance was a concern on Next, the test crew attempted to perform an insulation resistance test at 500 VDC; these

tap position 1 and, as the tap position results are presented in Table 4.

changed and additional portions of the

tap (or regulating) winding were added,

the results substantially deteriorated

further. Phase A and phase B test

results were unacceptable at higher tap

positions too. The significant differences Table 4: Insulation results obtained at 28°C

energize | May 2022 | 59