Page 62 - Energize May 2022

P. 62

TECHNICAL

An oil sample was taken from the transformer and sent to a lab for a DGA test. Results All evidence clearly pointed to

are shown in Table 5. a fault inside the transformer. The

remaining question was, where? To

localise the fault in the overall active

part of the transformer, SFRA testing

was carried out using Megger’s FRAX

101.

Table 5: Gas concentration from a transformer oil sample SFRA open circuit test results

(Figures 5 and 6) indicate a short circuit

The “latest before failure” DGA test results are not representative of a gassing issue, in phase C (blue traces). The fault had

especially for a furnace transformer. Numbers fall under condition 1 as specified by existing also affected the other two phases,

standards. This is a case where only an on-line gas monitor or a ‘lucky’ oil sample may have resulting in a completely asymmetrical

detected the incoming arcing fault before failure. response.

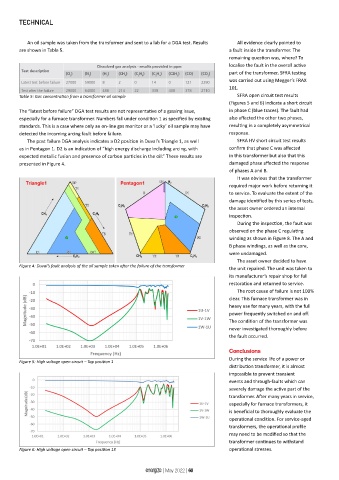

The post failure DGA analysis indicates a D2 position in Duval’s Triangle 1, as well SFRA HV short circuit test results

as in Pentagon 1. D2 is an indication of “high energy discharge including arcing, with confirm that phase C was affected

expected metallic fusion and presence of carbon particles in the oil.” These results are in this transformer but also that this

presented in Figure 4. damaged phase affected the response

of phases A and B.

It was obvious that the transformer

required major work before returning it

to service. To evaluate the extent of the

damage identified by this series of tests,

the asset owner ordered an internal

inspection.

During the inspection, the fault was

observed on the phase C regulating

winding as shown in Figure 8. The A and

B phase windings, as well as the core,

were undamaged.

The asset owner decided to have

Figure 4: Duval’s fault analysis of the oil sample taken after the failure of the transformer

the unit repaired. The unit was taken to

its manufacturer’s repair shop for full

restoration and returned to service.

The root cause of failure is not 100%

clear. This furnace transformer was in

heavy use for many years, with the full

power frequently switched on and off.

The condition of the transformer was

never investigated thoroughly before

the fault occurred.

Conclusions

During the service life of a power or

Figure 5: High voltage open circuit – Tap position 1

distribution transformer, it is almost

impossible to prevent transient

events and through-faults which can

severely damage the active part of the

transformer. After many years in service,

especially for furnace transformers, it

is beneficial to thoroughly evaluate the

operational condition. For service-aged

transformers, the operational profile

may need to be modified so that the

transformer continues to withstand

Figure 6: High voltage open circuit – Tap position 13 operational stresses.

energize | May 2022 | 60