Page 22 - EngineerIT March 2022

P. 22

MEASUREMENT

How to design a good vibration sensor

enclosure using modal analysis

By Richard Anslow, System Applications Engineer, Automation and Energy Business Unit at Analog Devices

In the article

A well-constructed mechanical enclosure design for a MEMS

accelerometer will ensure that high quality vibration data for

CbM is extracted from the monitored asset. The mechanical

enclosure used to house a MEMS accelerometer needs to have

a frequency response better than the integrated MEMS. This

article uses modal analysis to provide the natural frequencies

possible with enclosure designs. Guidance on vibration sensor

design is provided using theoretical and ANSYS modal simulation

examples. It is shown that geometry effects, such as enclosure

shape (such as a cylinder or a rectangle) and height dominate

the natural frequencies in enclosure design. Mechanical design

examples are provided for housing single-axis and tri-axial MEMS

accelerometers with 21 kHz resonant frequency. This article also

provides guidance on epoxy integration in enclosures, as well as Figure 1. The ADXL1002 MEMS accelerometer frequency response

cable installation and mounting options for sensors.

the Timoshenko equation of vibration will be used for the

simulation. We will cover this in more detail later in the article.

What is modal analysis and why is it important? A thick, short, cantilevered cylinder is similar to a vibration

A steel or aluminum enclosure is used to house a MEMS sensor mounted on industrial equipment, as shown in Figure

vibration sensor and provide solid attachment to monitored 2. The vibration sensor is fixed to industrial equipment using a

assets as well as water and dust resistance (IP67). A good stud mount. Both stud mounting and enclosure design require

metallic enclosure design will ensure high quality vibration careful characterisation so that mechanical resonances do

data is measured from the asset. Designing a good mechanical not affect the MEMS vibration frequencies of interest. Finite

enclosure requires an understanding of modal analysis. element methods (FEMs) using ANSYS or similar programs can

Modal analysis is used to understand the vibration be used as an efficient solver for the equation of vibration of a

characteristics of structures. Modal analysis provides the short, thick cylinder.

natural frequencies and normal modes (relative deformation)

of a design. The primary concern in modal analysis is to avoid

resonance, where the natural frequencies of a structural design

closely match that of the applied vibration load. For vibration

sensors, the natural frequencies of the enclosure must be

greater than that of the applied vibration load measured by the

MEMS sensor.

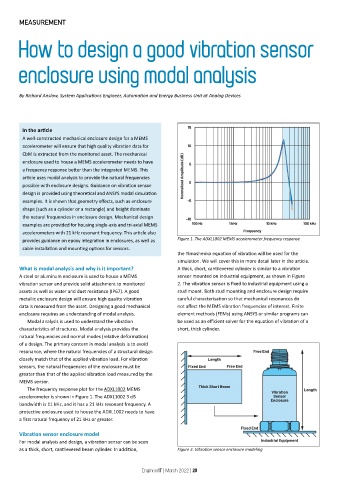

The frequency response plot for the ADXL1002 MEMS

accelerometer is shown in Figure 1. The ADXL1002 3 dB

bandwidth is 11 kHz, and it has a 21 kHz resonant frequency. A

protective enclosure used to house the ADXL1002 needs to have

a first natural frequency of 21 kHz or greater.

Vibration sensor enclosure model

For modal analysis and design, a vibration sensor can be seen

as a thick, short, cantilevered beam cylinder. In addition, Figure 2. Vibration sensor enclosure modeling

EngineerIT | March 2022 | 20