Page 48 - Energize July 2021

P. 48

TECHNICAL

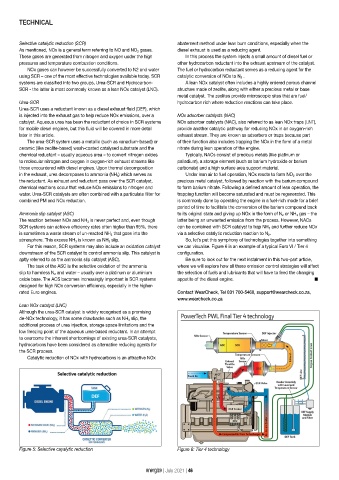

Selective catalytic reduction (SCR) abatement method under lean burn conditions, especially when the

As mentioned, NOx is a general term referring to NO and NO₂ gases. diesel exhaust is used as a reducing agent.

These gases are generated from nitrogen and oxygen under the high In this process the system injects a small amount of diesel fuel or

pressures and temperature combustion conditions. other hydrocarbon reductant into the exhaust upstream of the catalyst.

NOx gases can however be successfully converted to N2 and water The fuel or hydrocarbon reductant serves as a reducing agent for the

using SCR – one of the most effective technologies available today. SCR catalytic conversion of NOx to N₂ .

systems are classified into two groups, Urea-SCR and Hydrocarbon- A lean NOx catalyst often includes a highly ordered porous channel

SCR - the latter is most commonly known as a lean NOx catalyst (LNC). structure made of zeolite, along with either a precious metal or base

metal catalyst. The zeolites provide microscopic sites that are fuel/

Urea-SCR hydrocarbon rich where reduction reactions can take place.

Urea-SCR uses a reductant known as a diesel exhaust fluid (DEF), which

is injected into the exhaust gas to help reduce NOx emissions, over a NOx adsorber catalysts (NAC)

catalyst. Aqueous urea has been the reductant of choice in SCR systems NOx adsorber catalysts (NAC), also referred to as lean NOx traps (LNT),

for mobile diesel engines, but this fluid will be covered in more detail provide another catalytic pathway for reducing NOx in an oxygen-rich

later in this article. exhaust stream. They are known as adsorbers or traps because part

The urea-SCR system uses a metallic (such as vanadium-based) or of their function also includes trapping the NOx in the form of a metal

ceramic (like zeolite-based) wash-coated catalysed substrate and the nitrate during lean operation of the engine.

chemical reductant – usually aqueous urea – to convert nitrogen oxides Typically, NACs consist of precious metals (like platinum or

to molecular nitrogen and oxygen in oxygen-rich exhaust streams like palladium), a storage element (such as barium hydroxide or barium

those encountered with diesel engines. Upon thermal decomposition carbonate) and a high surface area support material.

in the exhaust, urea decomposes to ammonia (NH₃) which serves as Under lean air to fuel operation, NOx reacts to form NO₂ over the

the reductant. As exhaust and reductant pass over the SCR catalyst, precious metal catalyst, followed by reaction with the barium compound

chemical reactions occur that reduce NOx emissions to nitrogen and to form barium nitrate. Following a defined amount of lean operation, the

water. Urea-SCR catalysts are often combined with a particulate filter for trapping function will become saturated and must be regenerated. This

combined PM and NOx reduction. is commonly done by operating the engine in a fuel-rich mode for a brief

period of time to facilitate the conversion of the barium compound back

Ammonia slip catalyst (ASC) to its original state and giving up NOx in the form of N₂ or NH₃ gas – the

The reaction between NOx and NH₃ is never perfect and, even though latter being an unwanted emission from the process. However, NACs

SCR systems can achieve efficiency rates often higher than 95%, there can be combined with SCR catalyst to trap NH₃ and further reduce NOx

is sometimes a waste stream of un-reacted NH₃ that goes into the via a selective catalytic reduction reaction to N₂.

atmosphere. This excess NH₃ is known as NH₃ slip. So, let’s put this symphony of technologies together into something

For this reason, SCR systems may also include an oxidation catalyst we can visualise. Figure 6 is an example of a typical Euro VI / Tier 4

downstream of the SCR catalyst to control ammonia slip. This catalyst is configuration.

aptly referred to as the ammonia slip catalyst (ASC). Be sure to look out for the next instalment in this two-part article,

The task of the ASC is the selective oxidation of the ammonia where we will explore how all these emission control strategies will affect

slip to harmless N₂ and water – usually over a platinum or aluminium the selection of fuels and lubricants that will have to feed the changing

oxide base. The ACS becomes increasingly important in SCR systems appetite of the diesel engine. n

designed for high NOx conversion efficiency, especially in the higher-

rated Euro engines. Contact WearCheck, Tel 031 700-5460, support@wearcheck.co.za,

www.wearcheck.co.za

Lean NOx catalyst (LNC)

Although the urea-SCR catalyst is widely recognised as a promising

de-NOx technology, it has some drawbacks such as NH₃ slip, the

additional process of urea injection, storage space limitations and the

low freezing point of the aqueous urea-based reductant. In an attempt

to overcome the inherent shortcomings of existing urea-SCR catalysts,

hydrocarbons have been considered as alternative reducing agents for

the SCR process.

Catalytic reduction of NOx with hydrocarbons is an attractive NOx

Figure 5: Selective cayalytic reduction Figure 6: Tier 4 technology

energize | July 2021 | 46