Page 47 - Energize July 2021

P. 47

TECHNICAL

Diesel particulate filter (DPF)

One of the major combustion by-products of burning diesel is soot.

Soot comprises impure carbon particles resulting from the incomplete

combustion of diesel. A DPF is a device designed to remove soot from

diesel engine exhaust gases.

DPFs operate by trapping soot particles from the engine exhaust,

preventing them from reaching the environment. Unlike catalytic

converters which are designed to reduce gas-phase emissions flowing

through the catalyst, the particulate filter is designed to trap and retain

the solid particles, until the particles can be oxidised or burned in the

DPF itself, through a process called regeneration.

The most common DPFs in widespread use are cellular ceramic

honeycomb filters with channels that are plugged at alternating ends.

The ends of the filter, plugged in a checkerboard pattern, force the

soot-containing exhaust to flow through the porous filter walls. While

the exhaust gas can flow through the walls, the soot particles are

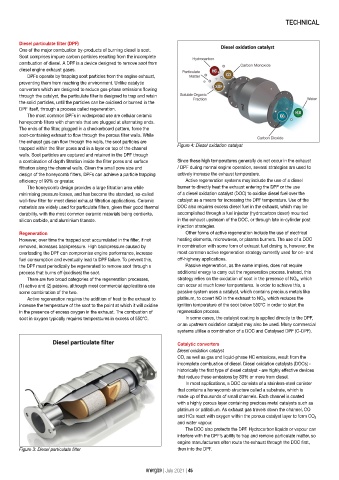

Figure 4: Diesel oxidation catalyst

trapped within the filter pores and in a layer on top of the channel

walls. Soot particles are captured and retained in the DPF through

a combination of depth filtration inside the filter pores and surface Since these high temperatures generally do not occur in the exhaust

filtration along the channel walls. Given the small pore size and / DPF during normal engine operation, several strategies are used to

design of the honeycomb filters, DPFs can achieve a particle trapping actively increase the exhaust temperature.

efficiency of 99% or greater. Active regeneration systems may include the use of a diesel

The honeycomb design provides a large filtration area while burner to directly heat the exhaust entering the DPF or the use

minimising pressure losses, and has become the standard, so-called of a diesel oxidation catalyst (DOC) to oxidise diesel fuel over the

wall-flow filter for most diesel exhaust filtration applications. Ceramic catalyst as a means for increasing the DPF temperature. Use of the

materials are widely used for particulate filters, given their good thermal DOC also requires excess diesel fuel in the exhaust, which may be

durability, with the most common ceramic materials being cordierite, accomplished through a fuel injector (hydrocarbon doser) mounted

silicon carbide, and aluminium titanate. in the exhaust upstream of the DOC, or through late in-cylinder post

injection strategies.

Regeneration Other forms of active regeneration include the use of electrical

However, over time the trapped soot accumulated in the filter, if not heating elements, microwaves, or plasma burners. The use of a DOC

removed, increases backpressure. High backpressure caused by in combination with some form of exhaust fuel dosing is, however, the

overloading the DPF can compromise engine performance, increase most common active regeneration strategy currently used for on- and

fuel consumption and eventually lead to DPF failure. To prevent this, off-highway applications.

the DPF must periodically be regenerated to remove soot through a Passive regeneration, as the name implies, does not require

process that burns off (oxidises) the soot. additional energy to carry out the regeneration process. Instead, this

There are two broad categories of the regeneration processes, strategy relies on the oxidation of soot in the presence of NO₂, which

(1) active and (2) passive, although most commercial applications use can occur at much lower temperatures. In order to achieve this, a

some combination of the two. passive system uses a catalyst, which contains precious metals like

Active regeneration requires the addition of heat to the exhaust to platinum, to covert NO in the exhaust to NO₂, which reduces the

increase the temperature of the soot to the point at which it will oxidise ignition temperature of the soot below 550°C in order to start the

in the presence of excess oxygen in the exhaust. The combustion of regeneration process.

soot in oxygen typically requires temperatures in excess of 550°C. In some cases, the catalyst coating is applied directly to the DPF,

or an upstream oxidation catalyst may also be used. Many commercial

systems utilise a combination of a DOC and Catalysed DPF (C-DPF).

Catalytic converters

Diesel oxidation catalyst

CO, as well as gas and liquid-phase HC emissions, result from the

incomplete combustion of diesel. Diesel oxidation catalysts (DOCs) -

historically the first type of diesel catalyst - are highly effective devices

that reduce these emissions by 80% or more from diesel.

In most applications, a DOC consists of a stainless-steel canister

that contains a honeycomb structure called a substrate, which is

made up of thousands of small channels. Each channel is coated

with a highly porous layer containing precious metal catalysts such as

platinum or palladium. As exhaust gas travels down the channel, CO

and HCs react with oxygen within the porous catalyst layer to form CO₂

and water vapour.

The DOC also protects the DPF. Hydrocarbon liquids or vapour can

interfere with the DPF’s ability to trap and remove particulate matter, so

engine manufacturers often route the exhaust through the DOC first,

Figure 3: Diesel particulate filter then into the DPF.

energize | July 2021 | 45