Page 56 - Energize November 2021

P. 56

TECHNICAL

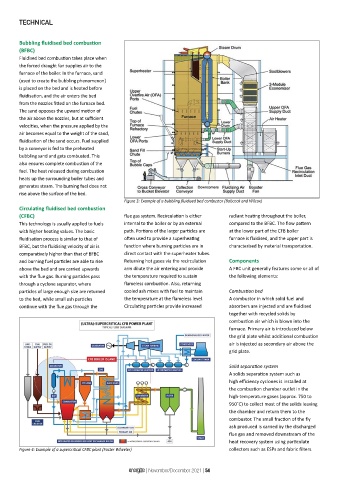

Bubbling fluidised bed combustion

(BFBC)

Fluidised bed combustion takes place when

the forced draught fan supplies air to the

furnace of the boiler. In the furnace, sand

(used to create the bubbling phenomenon)

is placed on the bed and is heated before

fluidisation, and the air enters the bed

from the nozzles fitted on the furnace bed.

The sand opposes the upward motion of

the air above the nozzles, but at sufficient

velocities, when the pressure applied by the

air becomes equal to the weight of the sand,

fluidisation of the sand occurs. Fuel supplied

by a conveyor is fed to the preheated

bubbling sand and gets combusted. This

also ensures complete combustion of the

fuel. The heat released during combustion

heats up the surrounding boiler tubes and

generates steam. The burning fuel does not

rise above the surface of the bed.

Figure 3: Example of a bubbling fluidised bed combustor (Babcock and Wilcox)

Circulating fluidised bed combustion

(CFBC) flue gas system. Recirculation is either radiant heating throughout the boiler,

This technology is usually applied to fuels internal to the boiler or by an external compared to the BFBC. The flow pattern

with higher heating values. The basic path. Portions of the larger particles are at the lower part of the CFB boiler

fluidisation process is similar to that of often used to provide a superheating furnace is fluidised, and the upper part is

BFBC, but the fluidising velocity of air is function where burning particles are in characterised by material transportation.

comparatively higher than that of BFBC direct contact with the superheater tubes.

and burning fuel particles are able to rise Returning hot gases via the recirculation Components

above the bed and are carried upwards arm dilute the air entering and provide A FBC unit generally features some or all of

with the flue gas. Burning particles pass the temperature required to sustain the following elements:

through a cyclone separator, where flameless combustion. Also, returning

particles of large enough size are returned cooled ash mixes with fuel to maintain Combustion bed

to the bed, while small ash particles the temperature at the flameless level. A combustor in which solid fuel and

continue with the flue gas through the Circulating particles provide increased absorbers are injected and are fluidised

together with recycled solids by

combustion air which is blown into the

furnace. Primary air is introduced below

the grid plate whilst additional combustion

air is injected as secondary air above the

grid plate.

Solid separation system

A solids separation system such as

high efficiency cyclones is installed at

the combustion chamber outlet in the

high-temperature gases (approx. 750 to

950˚C) to collect most of the solids leaving

the chamber and return them to the

combustor. The small fraction of the fly

ash produced is carried by the discharged

flue gas and removed downstream of the

heat recovery system using particulate

Figure 4: Example of a supercritical CFBC plant (Foster Wheeler) collectors such as ESPs and fabric filters.

energize | November/December 2021 | 54