Page 59 - Energize November 2021

P. 59

TECHNICAL

Obtaining crane operation synchronisation

with very tight skew tolerance

Information from Nidec

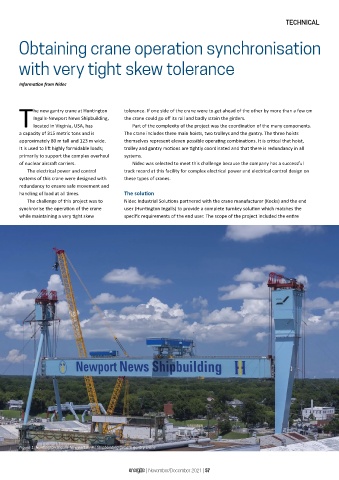

he new gantry crane at Huntington tolerance. If one side of the crane were to get ahead of the other by more than a few cm

Ingalls-Newport News Shipbuilding, the crane could go off its rail and badly strain the girders.

Tlocated in Virginia, USA, has Part of the complexity of the project was the coordination of the many components.

a capacity of 315 metric tons and is The crane includes three main hoists, two trolleys and the gantry. The three hoists

approximately 80 m tall and 123 m wide. themselves represent eleven possible operating combinations. It is critical that hoist,

It is used to lift highly formidable loads; trolley and gantry motions are tightly coordinated and that there is redundancy in all

primarily to support the complex overhaul systems.

of nuclear aircraft carriers. Nidec was selected to meet this challenge because the company has a successful

The electrical power and control track record at this facility for complex electrical power and electrical control design on

systems of this crane were designed with these types of cranes.

redundancy to ensure safe movement and

handling of load at all times. The solution

The challenge of this project was to Nidec Industrial Solutions partnered with the crane manufacturer (Kocks) and the end

synchronise the operation of the crane user (Huntington Ingalls) to provide a complete turnkey solution which matches the

while maintaining a very tight skew specific requirements of the end user. The scope of the project included the entire

Figure 1: Huntington Ingalls-Newport News Shipbuilding goliath gantry crane

energize | November/December 2021 | 57