Page 63 - Energize November 2021

P. 63

TECHNICAL

Medium voltage motor drives

by Mike Rycroft, Energize features editor

VFDs are commonly used with LV motors but have not found a great application in the MV range,

due to power limitations and reliability issues. The development of efficient high power electronic

devices makes wider and more reliable ranges of MV drives possible.

here are many different industries

that depend on medium voltage

Tdrives, including wastewater plants,

petrochemical, mining, food and drug and

general manufacturing. VFDs are part of

the powertrain for conveyor belts, mixers,

pumps, compressors and blowers. MV

VFDs are mainly used in the power range

where the difference in current draw

between low voltage and medium voltage

is significant.

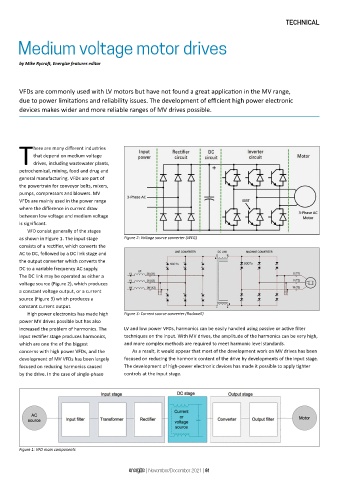

VFD consist generally of the stages

as shown in Figure 1. The input stage Figure 2: Voltage source converter (WEG)

consists of a rectifier, which converts the

AC to DC, followed by a DC link stage and

the output converter which converts the

DC to a variable frequency AC supply.

The DC link may be operated as either a

voltage source (Figure 2), which produces

a constant voltage output, or a current

source (Figure 3) which produces a

constant current output.

High power electronics has made high Figure 3: Current source converter (Rockwell)

power MV drives possible but has also

increased the problem of harmonics. The LV and low power VFDs, harmonics can be easily handled using passive or active filter

input rectifier stage produces harmonics, techniques on the input. With MV drives, the amplitude of the harmonics can be very high,

which are one the of the biggest and more complex methods are required to meet harmonic level standards.

concerns with high power VFDs, and the As a result, it would appear that most of the development work on MV drives has been

development of MV VFDs has been largely focused on reducing the harmonic content of the drive by developments of the input stage.

focused on reducing harmonics caused The development of high-power electronic devices has made it possible to apply tighter

by the drive. In the case of single-phase controls at the input stage.

Figure 1: VFD main components

energize | November/December 2021 | 61