Page 58 - Energize November 2021

P. 58

TECHNICAL

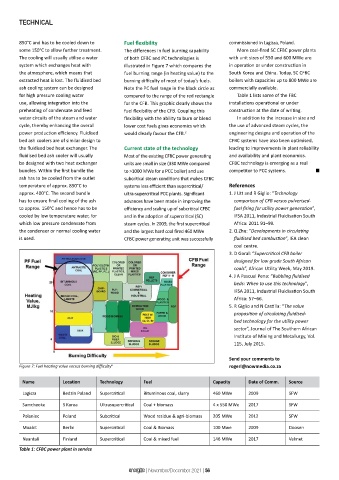

850°C and has to be cooled down to Fuel flexibility commissioned in Lagisza, Poland.

some 150°C to allow further treatment. The differences in fuel burning capability More coal-fired SC CFBC power plants

The cooling will usually utilise a water of both CFBC and PC technologies is with unit sizes of 550 and 600 MWe are

system which exchanges heat with illustrated in Figure 7 which compares the in operation or under construction in

the atmosphere, which means that fuel burning range (in heating value) to the South Korea and China. Today, SC CFBC

extracted heat is lost. The fluidised bed burning difficulty of most of today’s fuels. boilers with capacities up to 800 MWe are

ash cooling system can be designed Note the PC fuel range in the black circle as commercially available.

for high pressure cooling water compared to the range of the red rectangle Table 1 lists some of the FBC

use, allowing integration into the for the CFB. This graphic clearly shows the installations operational or under

preheating of condensate and feed fuel flexibility of the CFB. Coupling this construction at the date of writing.

water circuits of the steam and water flexibility with the ability to burn or blend In addition to the increase in size and

cycle, thereby enhancing the overall lower cost fuels gives economics which the use of advanced steam cycles, the

power production efficiency. Fluidised would clearly favour the CFB. 2 engineering designs and operation of the

bed ash coolers are of similar design to CFBC systems have also been optimised,

the fluidised bed heat exchanger. The Current state of the technology leading to improvements in plant reliability

fluidised bed ash cooler will usually Most of the existing CFBC power generating and availability and plant economics.

be designed with two heat exchanger units are small in size (330 MWe compared CFBC technology is emerging as a real

bundles. Within the first bundle the to >1000 MWe for a PCC boiler) and use competitor to PCC systems. n

ash has to be cooled from the outlet subcritical steam conditions that makes CFBC

temperature of approx. 850°C to systems less efficient than supercritical/ References

approx. 400°C. The second bundle ultra-supercritical PCC plants. Significant 1. J Utt and R Giglio: “Technology

has to ensure final cooling of the ash advances have been made in improving the comparison of CFB versus pulverised-

to approx. 150°C and hence has to be efficiency and scaling up of subcritical CFBC fuel firing for utility power generation”,

cooled by low temperature water, for and in the adoption of supercritical (SC) IFSA 2011, Industrial Fluidisation South

which low pressure condensate from steam cycles. In 2009, the first supercritical Africa: 2011 91–99.

the condenser or normal cooling water and the largest hard coal fired 460 MWe 2. Q Zhu: “Developments in circulating

is used. CFBC power generating unit was successfully fluidised bed combustion”, IEA clean

coal centre.

3. D Goral: “Supercritical CFB boiler

designed for low grade South African

coals”, African Utility Week, May 2019.

4. J A Pascual Pena: “Bubbling fluidised

beds: When to use this technology”,

IFSA 2011, Industrial Fluidisation South

Africa: 57–66.

5. R Giglio and N Castilla: “The value

proposition of circulating fluidised-

bed technology for the utility power

sector”, Journal of The Southern African

Institute of Mining and Metallurgy, Vol.

115, July 2015.

Send your comments to

Figure 7: Fuel heating value versus burning difficulty 6 rogerl@nowmedia.co.za

Name Location Technology Fuel Capacity Date of Comm. Source

Lagisza Bedzin Poland Supercritical Bituminous coal, slurry 460 MWe 2009 SFW

Samcheoke S Korea Ultrasupercritical Coal + biomass 4 x 550 MWe 2017 SFW

Polaniec Poland Subcritical Wood residue & agri-biomass 205 MWe 2012 SFW

Moabit Berlin Supercritical Coal & Biomass 100 Mwe 2009 Doosen

Naantali Finland Supercritical Coal & mixed fuel 146 MWe 2017 Valmet

Table 1: CFBC power plant in service

energize | November/December 2021 | 56