Page 71 - Energize October 2022

P. 71

TECHNICAL

• 12% decrease in total weight In the event of failure, the force applied to the structure

• 11% decrease in case weight may approximate 360 PSI due to the steep wave front and

• 10% decrease in oil weight high velocity, representing a loading sufficient to distort the

container or shear the holding bolts and possibly cause a

• 13% decrease in core & coil weight transformer oil fire.

• 7 to 33% decrease in electrical clearances

• 9% decrease in no-load losses Case example: rectifier transformer

• 3.5% decrease in load losses The DGA on this transformer showed abnormal gas production

• 25% increase in number of pumps of hydrogen, methane, ethylene and ethane about 20 months

Table 1: Transformer comparisons between the 1970s and 1980s after energising. The fault condition was diagnosed as a thermal

fault of medium temperature in the range 300°C and 700°C. The

What causes a power transformer to fail? recommendation at 30/09/1996 was to remove the unit from

It is generally believed that failure occurs when a transformer service for inspection.

component or structure is no longer able to withstand the See Table 2 giving the name plate data and Figure 4 shows

stresses imposed on it during operation. the DGA trend with Figure 5 showing the DGA signature.

It is also important to distinguish the fault and the failure.

A fault is mainly attributed to permanent and irreversible Make: TRAFO-UNION

change in transformer’s condition. The risk of a failure Year Manufactured: 1995

occurrence depends not only on the stage of the fault Primary Voltage: 132 kV

developing but also the transformer functional component VA Rating: 93.5 MVA

involved. The failure could be repairable on site, depending on Vector Group: 111,D11+1

the type of fault as well as the severity of the failure. Secondary Voltage: 1060V

Tap Changer: On Load

Power transformer failures are commonly associated with Oil Volume Litres: 33908

localised stress concentrations (faults), which can occur for

several reasons, including: Conservator: Yes

• Design and manufacture weakness, e.g., poor design Table 2: Name plate data

of conductor sizing and transpositions, poor joints,

poor stress shield and shunts, poor design of clamping,

inadequate local cooling, high leakage flux, poor

workmanship, etc.

• Weakness in transformer design, construction and

materials could be covered by low loading. However,

increasing loading and extended periods of in-service

usage will uncover these weaknesses

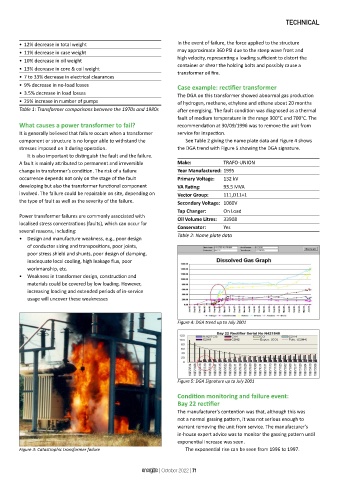

Figure 4: DGA trend up to July 2001

Figure 5: DGA Signature up to July 2001

Condition monitoring and failure event:

Bay 22 rectifier

The manufacturer’s contention was that, although this was

not a normal gassing pattern, it was not serious enough to

warrant removing the unit from service. The manufacturer’s

in-house expert advice was to monitor the gassing pattern until

exponential increase was seen.

Figure 3: Catastrophic transformer failure The exponential rise can be seen from 1996 to 1997.

energize | October 2022 | 71