Page 72 - Energize October 2022

P. 72

TECHNICAL

The frequency of oil sampling was increased as the

transformer was under warranty and the manufacturer

ultimately had the decision on whether to remove a transformer

from service for inspection. It is interesting to note the gas

production after July 1997 showed only a slight rate of rise.

However, after the oil de-gassing in July 2001, the same

phenomenon of exponential gas production followed by a

levelling off was seen (See Figure 3). This can be explained in

part by the IEC 60599 code that reports that there can be gas

diffusion losses for in service equipment. However, there is no

agreement concerning the magnitude.

There are also reports of gas adsorption by the solid (paper)

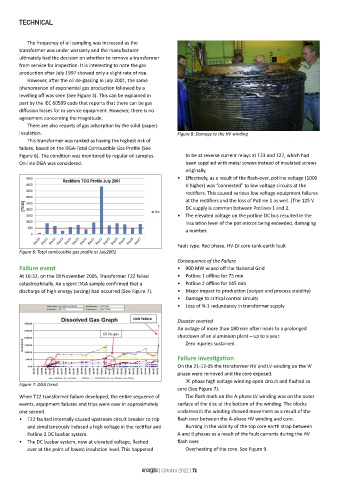

insulation. Figure 8: Damage to the HV winding

This transformer was ranked as having the highest risk of

failure, based on the DGA-Total Combustible Gas Profile (See

Figure 6). The condition was monitored by regular oil samples. to be at reverse current relays at T23 and T27, which had

On-line DGA was considered. been supplied with metal screws instead of insulated screws

originally.

• Effectively, as a result of the flash-over, potline voltage (1000

V higher) was “connected” to low voltage circuits at the

rectifiers. This caused various low voltage equipment failures

at the rectifiers and the loss of Potline 1 as well. (The 125 V

DC supply is common between Potlines 1 and 2.

• The elevated voltage on the potline DC bus resulted in the

insulation level of the pot micros being exceeded, damaging

a number.

Fault type. Red phase, HV-LV-core-tank-earth fault

Figure 6: Total combustible gas profile at July2001

Consequence of the Failure

Failure event • 900 MW wiped off the National Grid

At 16:32, on the 18 November 2005, Transformer T22 failed • Potline 1 offline for 75 min

catastrophically. An urgent DGA sample confirmed that a • Potline 2 offline for 145 min

discharge of high energy (arcing) had occurred (See Figure 7). • Major impact to production (output and process stability)

• Damage to critical control circuits

• Loss of N-1 redundancy in transformer supply

Disaster averted

An outage of more than 180 min often leads to a prolonged

shutdown of an aluminium plant – up to a year.

Zero injuries sustained.

Failure investigation

On the 21-12-05 the transformer HV and LV winding on the ‘A’

phase were removed and the core exposed.

‘A’ phase high voltage winding open circuit and flashed to

Figure 7: DGA trend

core (See Figure 7).

When T22 transformer failure developed, the entire sequence of The flash mark on the A-phase LV winding was on the outer

events, equipment failures and trips were over in approximately surface of the disc at the bottom of the winding. The blocks

one second. underneath the winding showed movement as a result of the

• T22 faulted internally caused upstream circuit breaker to trip flash over between the A-phase HV winding and core.

and simultaneously induced a high voltage in the rectifier and Burning in the vicinity of the top core earth strap between

Potline 2 DC busbar system. A and B phases as a result of the fault currents during the HV

• The DC busbar system, now at elevated voltage, flashed flash over.

over at the point of lowest insulation level. This happened Overheating of the core. See Figure 9.

energize | October 2022 | 72