Page 23 - EngineerIT January 2022

P. 23

ICT – RADIO COMMUNICATION

Solder mask variance and stencil invariance

Along with the solder stencil, the solder mask on the PCB (which

usually has a familiar green colour) defines where solder paste

should be applied to the PCB. A popular design approach involves

making the solder mask openings (apertures) slightly smaller than

the metal pads underneath (so-called solder mask defined pads).

Many PCBs use liquid photo-imageable (LPI) solder masks

that meet the IPC-SM-840 Class 3 standard. Depending on the

fabrication lot, vendor, etc., the solder mask apertures can vary in

size and be misaligned due to solder mask registration errors. An

example of a solder mask with varying apertures is shown in Figure

3 (highlighted with red rectangles).

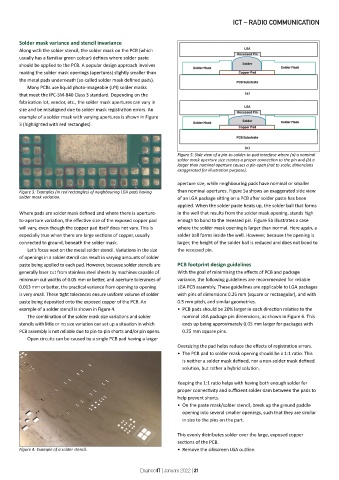

Figure 5: Side view of a pin-to-solder-to-pad interface where (a) a nominal

solder mask aperture size creates a proper connection to the pin and (b) a

larger than nominal aperture causes a pin open (not to scale; dimensions

exaggerated for illustration purpose).

aperture size, while neighbouring pads have nominal or smaller

Figure 3: Examples (in red rectangles) of neighbouring LGA pads having than nominal apertures. Figure 5a shows an exaggerated side view

solder mask variation. of an LGA package sitting on a PCB after solder paste has been

applied. When the solder paste heats up, the solder ball that forms

Where pads are solder mask defined and where there is aperture- in the well that results from the solder mask opening, stands high

to-aperture variation, the effective size of the exposed copper pad enough to bond to the recessed pin. Figure 5b illustrates a case

will vary, even though the copper pad itself does not vary. This is where the solder mask opening is larger than normal. Here again, a

especially true when there are large sections of copper, usually solder ball forms inside the well. However, because the opening is

connected to ground, beneath the solder mask. larger, the height of the solder ball is reduced and does not bond to

Let’s focus next on the metal solder stencil. Variations in the size the recessed pin.

of openings in a solder stencil can result in varying amounts of solder

paste being applied to each pad. However, because solder stencils are PCB footprint design guidelines

generally laser cut from stainless steel sheets by machines capable of With the goal of minimising the effects of PCB and package

minimum cut widths of 0.05 mm or better, and aperture tolerances of variance, the following guidelines are recommended for reliable

0.013 mm or better, the practical variance from opening to opening LGA PCB assembly. These guidelines are applicable to LGA packages

is very small. These tight tolerances ensure uniform volume of solder with pins of dimensions 0.25 mm (square or rectangular), and with

paste being deposited onto the exposed copper of the PCB. An 0.5 mm pitch, and similar geometries.

example of a solder stencil is shown in Figure 4. • PCB pads should be 20% larger in each direction relative to the

The combination of the solder mask size variations and solder nominal LGA package pin dimensions, as shown in Figure 6. This

stencils with little or no size variation can set up a situation in which ends up being approximately 0.05 mm larger for packages with

PCB assembly is not reliable due to pin-to-pin shorts and/or pin opens. 0.25 mm square pins.

Open circuits can be caused by a single PCB pad having a larger

Oversizing the pad helps reduce the effects of registration errors.

• The PCB pad to solder mask opening should be a 1:1 ratio. This

is neither a solder mask defined, nor a non-solder mask defined

solution, but rather a hybrid solution.

Keeping the 1:1 ratio helps with having both enough solder for

proper connectivity and sufficient solder dam between the pads to

help prevent shorts.

• On the paste mask/solder stencil, break up the ground paddle

opening into several smaller openings, such that they are similar

in size to the pins on the part.

This evenly distributes solder over the large, exposed copper

sections of the PCB.

Figure 4: Example of a solder stencil. • Remove the silkscreen LGA outline.

EngineerIT | January 2022 | 21