Page 24 - EngineerIT January 2022

P. 24

ICT – RADIO COMMUNICATION

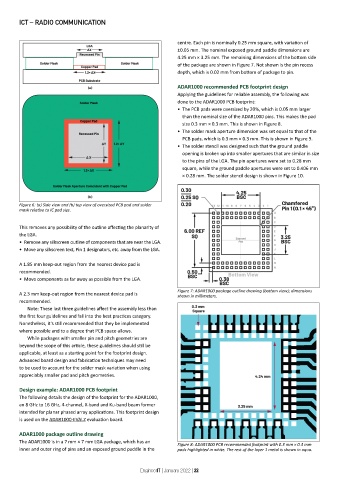

centre. Each pin is nominally 0.25 mm square, with variation of

±0.05 mm. The nominal exposed ground paddle dimensions are

4.25 mm × 3.25 mm. The remaining dimensions of the bottom side

of the package are shown in Figure 7. Not shown is the pin recess

depth, which is 0.02 mm from bottom of package to pin.

ADAR1000 recommended PCB footprint design

Applying the guidelines for reliable assembly, the following was

done to the ADAR1000 PCB footprint:

• The PCB pads were oversized by 20%, which is 0.05 mm larger

than the nominal size of the ADAR1000 pins. This makes the pad

size 0.3 mm × 0.3 mm. This is shown in Figure 8.

• The solder mask aperture dimension was set equal to that of the

PCB pads, which is 0.3 mm × 0.3 mm. This is shown in Figure 9.

• The solder stencil was designed such that the ground paddle

opening is broken up into smaller apertures that are similar in size

to the pins of the LGA. The pin apertures were set to 0.28 mm

square, while the ground paddle apertures were set to 0.406 mm

× 0.28 mm. The solder stencil design is shown in Figure 10.

Figure 6: (a) Side view and (b) top view of oversized PCB pad and solder

mask relative to IC pad size.

This removes any possibility of the outline affecting the planarity of

the LGA.

• Remove any silkscreen outline of components that are near the LGA.

• Move any silkscreen text, Pin 1 designators, etc. away from the LGA.

A 1.85 mm keep-out region from the nearest device pad is

recommended.

• Move components as far away as possible from the LGA.

Figure 7: ADAR1000 package outline drawing (bottom view); dimensions

A 2.3 mm keep-out region from the nearest device pad is shown in millimeters.

recommended.

Note: These last three guidelines affect the assembly less than

the first four guidelines and fall into the best practices category.

Nonetheless, it’s still recommended that they be implemented

where possible and to a degree that PCB space allows.

While packages with smaller pin and pitch geometries are

beyond the scope of this article, these guidelines should still be

applicable, at least as a starting point for the footprint design.

Advanced board design and fabrication techniques may need

to be used to account for the solder mask variation when using

appreciably smaller pad and pitch geometries.

Design example: ADAR1000 PCB footprint

The following details the design of the footprint for the ADAR1000,

an 8 GHz to 16 GHz, 4-channel, X-band and Ku-band beam former

intended for planar phased array applications. This footprint design

is used on the ADAR1000-EVALZ evaluation board.

ADAR1000 package outline drawing

The ADAR1000 is in a 7 mm × 7 mm LGA package, which has an Figure 8: ADAR1000 PCB recommended footprint with 0.3 mm × 0.3 mm

inner and outer ring of pins and an exposed ground paddle in the pads highlighted in white. The rest of the layer 1 metal is shown in aqua.

EngineerIT | January 2022 | 22