Page 35 - Energize January 2022

P. 35

NEWS

Condition monitoring reports now available by WhatsApp

ne of the latest technological innovations employed by condition monitoring

specialists, WearCheck, is enabling the company’s sophisticated online system to

Osend customers their reports via WhatsApp.

The company’s managing director, Neil Robinson, says WearCheck is constantly exploring

how technology can enhance the customer experience as well as continuously improving

condition monitoring techniques.

IT manager Eddie Perumal explains how it works, “WhatsApp has proven its convenience

as an integral part of everyone’s daily life, and it adds value by allowing us to communicate

in real-time with maintenance teams who may be on the factory floor with their mobile

phone, rather than waiting until they are sitting behind a desk checking emails. Therefore,

we felt it was fitting to incorporate the option of communicating with our customers via

WhatsApp”, he said.

Customers can select from three message options – a single page report, a two-page

report or status. Reports include fleet information, problem type and diagnosis. This feature

applies to critical and urgent samples.

Another powerful reporting tool is WearCheck Online, a web-based system which allows

customers to view their sample report and fleet information, as well as submit their sample

registration details and feedback.

WearCheck Online comes with a variety of features to assist customers to manage their oil

analysis programme. Some of these include:

• Current samples list, which shows unread reports.

• Print sampling labels using A4 self-adhesive labels.

• Trend-based graphs, problem-type graphs and pivot tables.

• Component analysis: view the results of one or more components in a single graph.

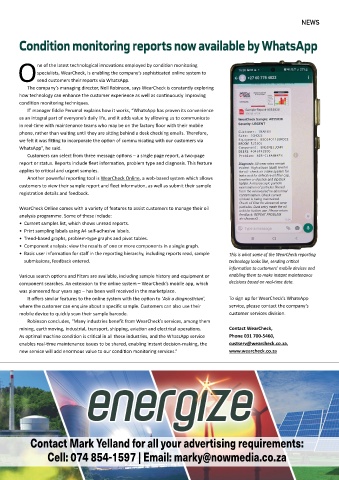

• Basic user information for staff in the reporting hierarchy, including reports read, sample This is what some of the WearCheck reporting

submissions, feedback entered. technology looks like, sending critical

information to customers’ mobile devices and

Various search options and filters are available, including sample history and equipment or enabling them to make instant maintenance

component searches. An extension to the online system – WearCheck’s mobile app, which decisions based on real-time data.

was pioneered four years ago – has been well received in the marketplace.

It offers similar features to the online system with the option to ‘Ask a diagnostician’, To sign up for WearCheck’s WhatsApp

where the customer can enquire about a specific sample. Customers can also use their service, please contact the company’s

mobile device to quickly scan their sample barcode. customer services division.

Robinson concludes, “Many industries benefit from WearCheck’s services, among them

mining, earthmoving, industrial, transport, shipping, aviation and electrical operations. Contact WearCheck,

As optimal machine condition is critical in all these industries, and the WhatsApp service Phone 031 700-5460,

enables real-time maintenance issues to be shared, enabling instant decision-making, the custserv@wearcheck.co.za,

new service will add enormous value to our condition monitoring services.” www.wearcheck.co.za

Contact Mark Yelland for all your advertising requirements:

Cell: 074 854-1597 | Email: marky@nowmedia.co.za