Page 40 - Energize November 2022

P. 40

TECHNICAL

When the variable speed drive operates in torque control mode,

the speed is determined by the load. Likewise, when operated in

speed control, the torque is determined by the load.

Four reasons to invest in variable speed drives to

improve energy efficiency

Here’s why you should invest in variable speed drives (VSDs) to

improve energy efficiency of your various applications, such as

pump, fan, conveyor and compressor systems:

Figure 2: Smooth the DC wave: DC power is fed into capacitors,

smoothing the wave and producing a clean DC supply. • Improved operational efficiency: the need for manual labour

is eliminated as the system controlled by drives can be

automated, thus saving man-hours and labour costs.

• Savings on the electricity bill: variable speed drives use only

the needed amount of energy by running the motors at

partial load, which can result up to 50% reduction in energy

consumption of the drive system.

• Savings in capital expenditure: immediate reduction in

electrical consumption ensures fast financial payback for the

VSD investment in pump and fan applications, even within

Figure 3: Convert DC to variable AC: The variable speed drive calculates months of installation.

the motor’s required voltage and current. DC power is then fed into an • Savings in maintenance and spare part costs: with drives,

inverter producing AC power at the precise voltage and current needed.

the stress on the mechanical equipment during start-up and

operation can be minimized, ensuring longer lifetime of the

equipment.

These types of valuable gains can be achieved not only in

large industrial operations but in smaller installations as

well. You can estimate your potential energy and cost savings

gained by low voltage AC variable speed drive control,

compared to traditional methods like throttles and valves, by

using ABB’s free EnergySave Calculator for compressors, fans

and pumps.

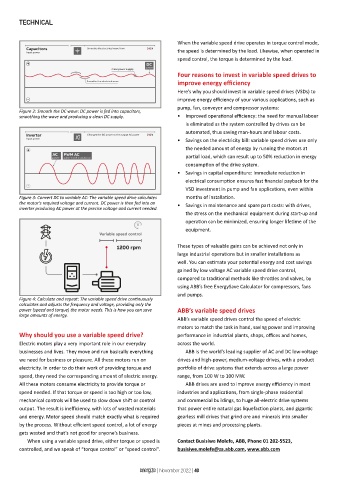

Figure 4: Calculate and repeat: The variable speed drive continuously

calculates and adjusts the frequency and voltage, providing only the

power (speed and torque) the motor needs. This is how you can save ABB’s variable speed drives

large amounts of energy.

ABB’s variable speed drives control the speed of electric

motors to match the task in hand, saving power and improving

Why should you use a variable speed drive? performance in industrial plants, shops, offices and homes,

Electric motors play a very important role in our everyday across the world.

businesses and lives. They move and run basically everything ABB is the world’s leading supplier of AC and DC low-voltage

we need for business or pleasure. All these motors run on drives and high-power, medium-voltage drives, with a product

electricity. In order to do their work of providing torque and portfolio of drive systems that extends across a large power

speed, they need the corresponding amount of electric energy. range, from 100 W to 100 MW.

All these motors consume electricity to provide torque or ABB drives are used to improve energy efficiency in most

speed needed. If that torque or speed is too high or too low, industries and applications, from single-phase residential

mechanical controls will be used to slow down shift or control and commercial buildings, to huge all-electric drive systems

output. The result is inefficiency, with lots of wasted materials that power entire natural gas liquefaction plants, and gigantic

and energy. Motor speed should match exactly what is required gearless mill drives that grind ore and minerals into smaller

by the process. Without efficient speed control, a lot of energy pieces at mines and processing plants.

gets wasted and that’s not good for anyone’s business.

When using a variable speed drive, either torque or speed is Contact Busisiwe Molefe, ABB, Phone 01 202-5523,

controlled, and we speak of “torque control” or “speed control”. busisiwe.molefe@za.abb.com, www.abb.com

energize | November 2022 | 40