Page 36 - EngineerIT June 2022

P. 36

INDUSTRY, TECHNOLOGY, PRODUCTS AND INNOVATION

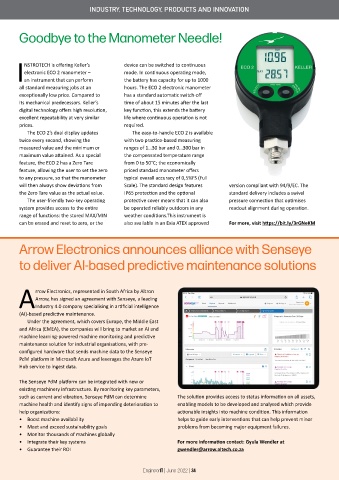

Goodbye to the Manometer Needle!

NSTROTECH is offering Keller’s device can be switched to continuous

electronic ECO 2 manometer – mode. In continuous operating mode,

Ian instrument that can perform the battery has capacity for up to 1000

all standard measuring jobs at an hours. The ECO 2 electronic manometer

exceptionally low price. Compared to has a standard automatic switch-off

its mechanical predecessors. Keller’s time of about 15 minutes after the last

digital technology offers high resolution, key function, this extends the battery

excellent repeatability at very similar life where continuous operation is not

prices. required.

The ECO 2’s dual display updates The easy-to-handle ECO 2 is available

twice every second, showing the with two practice-based measuring

measured value and the minimum or ranges of 1…30 bar and 0…300 bar in

maximum value attained. As a special the compensated temperature range

feature, the ECO 2 has a Zero Tare from 0 to 50°C; the economically

feature, allowing the user to set the zero priced standard manometer offers

to any pressure, so that the manometer typical overall accuracy of 0,5%FS (Full

will then always show deviations from Scale). The standard design features version compliant with 94/9/EC. The

the Zero Tare value as the actual value. IP65 protection and the optional standard delivery includes a swivel

The user-friendly two-key operating protective cover means that it can also pressure connection that optimises

system provides access to the entire be operated reliably outdoors in any readout alignment during operation.

range of functions: the stored MAX/MIN weather conditions.This instrument is

can be erased and reset to zero, or the also available in an Exia ATEX approved For more, visit https://bit.ly/3rGNeKM

Arrow Electronics announces alliance with Senseye

to deliver AI-based predictive maintenance solutions

rrow Electronics, represented in South Africa by Altron

Arrow, has signed an agreement with Senseye, a leading

AIndustry 4.0 company specialising in artificial intelligence

(AI)-based predictive maintenance.

Under the agreement, which covers Europe, the Middle East

and Africa (EMEA), the companies will bring to market an AI and

machine learning-powered machine monitoring and predictive

maintenance solution for industrial organisations, with pre-

configured hardware that sends machine data to the Senseye

PdM platform in Microsoft Azure and leverages the Azure IoT

Hub service to ingest data.

The Senseye PdM platform can be integrated with new or

existing machinery infrastructure. By monitoring key parameters,

such as current and vibration, Senseye PdM can determine The solution provides access to status information on all assets,

machine health and identify signs of impending deterioration to enabling models to be developed and analysed which provide

help organizations: actionable insights into machine condition. This information

• Boost machine availability helps to guide early interventions that can help prevent minor

• Meet and exceed sustainability goals problems from becoming major equipment failures.

• Monitor thousands of machines globally

• Integrate their key systems For more information contact: Gyula Wendler at

• Guarantee their ROI gwendler@arrow.altech.co.za

EngineerIT | June 2022 | 34